New CNC Machining Technology Trends for 2025

- Posted By: Zach Schantz

The CNC machining industry is on the cutting edge of technological advancement, often seeing early adoption of new technology. To stay competitive, CNC machining businesses are compelled to use the latest, most efficient, and most precise new CNC machining technology each year. This competition amongst machine shops has led to greater availability and lower cost and is shaping a bright future for the CNC machining industry. Outlooks are bullish on several trends, some of which are new developments, while others build on successful trends from last year. So what’s the future of CNC machining? Let’s find out.

Software Advancement, Computer Modeling, and Project Simulation

Advancements in industrial software have the potential to greatly improve precision, efficiency, and consistency over the next year. Computer-aided design (CAD), often used for rapid prototyping services, leads to the generation of more fabrication-friendly parts, making the machining process more efficient by eliminating the need to replace parts that turn out not to function properly. Computer-aided manufacturing has a similar effect but on manufacturing efficiency and precision rather than design-related factors.

Together, these important new pieces of CNC machining technology allow for advanced techniques, such as computer modeling the part to be machined and simulating how it will interact with other parts in a project. By modeling and simulating use, it becomes much easier to spot design flaws, which can be addressed more quickly.

Automated Quote Generation

Another beneficial new type of AI-driven software allows for the automatic generation of a quote for any viable design it evaluates. The future of CNC machining is largely reliant on automation, and by automating how quotes are given, manpower is freed up to focus on the machining itself. Quotes are given more quickly and accurately, in a fraction of the time necessary to manually create a quote, and productivity increases as time is saved. Some clients, however, still like to do business with people rather than software, but they aren’t as common in the CNC machining industry. Outlooks on this type of new CNC machining technology indicate that automated quote generation will continue to improve and proliferate, likely becoming the industry standard in a short time.

Continued Improvements in Multi-Axis Machining

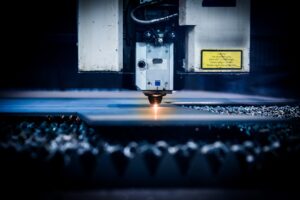

Multi-axis machining is a feature of some new CNC machining technologies and will likely become more commonplace as they become more affordable. This new function allows for the creation of complex parts that would be prohibitively difficult or expensive with traditional CNC machining in functions such as CNC milling and CNC laser cutting. In the future, most companies will likely utilize multi-axis machining, at least for some projects, but for now, it’s a fairly new and advanced technology in the CNC machining space and, as such, only sees limited practical use.

Environmental Consciousness and Sustainability

The old saying “reduce, reuse, recycle” has largely been adopted by the CNC machining industry. As the outlook of the planet looks increasingly unpredictable, a larger number of industries are looking for ways to reduce their impact on the environment. This is a good move for a number of reasons, the most important of which is the inability to continue as an industry if environmental regulations become stricter.

In the short term, practical reasoning also indicates that eco-friendly considerations are a good business decision. As new CNC machining technology in 2025 and beyond makes the machining process more efficient, energy usage will come down. By reducing the amount of energy used for a given project, a company saves money via the lower cost of electricity per project. Furthermore, there are often tax incentives and other publicly funded programs that can be accessed by companies that meet certain environmental benchmarks. The outlook for the CNC machining industry is that a growing number of fabrication shops will adopt more eco-friendly practices.

Machine Learning and Artificial Intelligence

As in many other sectors, artificial intelligence is having a major impact on new technology developed for the CNC machining industry. One impactful development that will be used by more and more companies is AI-driven machine learning. By self-reporting maintenance needs, tracking and correcting issues of quality of output, and optimizing tool usage, machine learning brings the future of CNC machining to today.

Advanced Robotics and Automation

Robotics have served plastic and metal fabrication shops well since their advent, and the outlook in the CNC machining industry indicates further increases in the capabilities of robotic machinery. Robotics take over repetitive or difficult tasks that would normally occupy much of a worker’s time, freeing them up to work on more critical tasks while the robot carries out its assigned task. This, in turn, leads to a more productive workforce.

Automation is a relatively new CNC machining technology, and it goes hand in hand with the recent advances in robotics. Automated CNC machinery can, theoretically, run around the clock without human supervision. While ideally, a person would be on-site for maintenance, malfunctions, and emergencies, this greatly increases productive capacity. Automation also reduces human error, leading to a higher-quality product.

Ability to Monitor Machinery in Real Time

The ability to monitor CNC machinery during production is essential for any modern custom fabrication shop. The ability to see exactly when a tool wears down or identify causes of reduced quality output is invaluable to these companies, as it allows for predictive, rather than reactive, maintenance. New CNC machining technology can provide a steady stream of data about the machinery’s functionality; issues with a machine can be responded to before they become more severe or do permanent damage to the machinery. Monitoring CNC machinery in real time will both directly and indirectly improve the quality and efficiency of a machining company, as problems can be addressed in a more timely fashion, resulting in less downtime and more consistent quality. Being able to monitor a machine’s performance 24 hours a day is a certain part of the future of CNC machining.

Move Away from In-House Machining

Many companies that design parts and products aren’t interested in doing their own machining. The equipment is prohibitively expensive for some and an impractical allocation of manpower for others. The new CNC machining technologies developed over the last few years are intended for dedicated CNC machining facilities and are usually quite costly to purchase and set up. As a result, in-house machining has seen a decline, while specialized CNC machining has seen an uptick in recent years. These companies can produce large quantities of parts relatively quickly and cost-effectively. Some companies have even done away with minimum orders, allowing for both small- and large-scale projects to be completed without the need for in-house machining. The future of CNC machining is the specialist shop.

Take Advantage of the Latest Advancements

At Schantz Machining and Fabrication, we use new CNC machining technology in our machining department and have seen improvements in several areas by doing so. We use a live tool lathe, which can do the work of multiple machines simultaneously, speeding up production without sacrificing quality in the process. This gives us the ability to guarantee shorter lead times than many others in the industry. Our software and fabrication strategies save time and expense, allowing us to offer low-volume production machining, meaning that we are equipped to serve both small-scale and large-scale needs. Talk to a CNC design consultant at Schantz Fabrication about your project and how we’ll use new CNC machining technology on your project.

Other Articles of Interest

New CNC Machining Technology Trends for 2025

New CNC Machining Technology Trends for 2025 The CNC machining industry is on the cutting edge of technological advancement, often seeing early adoption of new

What Is a Custom Fabrication Shop?: A Review of Our Capabilities

What Is a Custom Fabrication Shop?: A Review of Our Capabilities The Schantz family began building custom trailers and trucks for the food industry over

What Is CNC Laser Cutting?

What Is CNC Laser Cutting? Precision and efficiency are paramount when it comes to manufacturing and fabrication. It is for these reasons that the manufacturing

Titanium vs Steel Choice

Titanium vs Steel: Whats the Better Choice? In the manufacturing world and the machining industry, titanium and steel are the top choices when it comes

Top Challenges to Consider When Machining Titanium

Top Challenges to Consider when Machining Titanium Titanium’s high strength, high corrosion resistance, low weight, and other distinctive characteristics make it a material that is

What is Turning CNC Turning Milling for Custom Machining

What is Turning? CNC Turning & Milling for Custom Machining CNC machining encompasses several processes, the outcomes of which can include tools, parts, or components

How Can We Help You Today?

From initial design, to prototypes and full production,

you can count on us to deliver quality parts,

on time and on budget!