CNC Milling Machine Services

Multi-Axis Milling

Schantz Machine and Fabrication offers a wide range of CNC milling services. We have a variety of custom CNC milling centers that enable us to produce simple or complex part geometries with high speed and precision. Our goal is to give you a level of service that you cannot get anywhere else. As a leading CNC milling company with over 60+ years of experience in metal fabrication, we have mastered the art of delivering tailor-made solutions that meet the unique needs of our clients.

3-, 4-, or 5-Axis CNC Milling: Why Do You Care?

Custom metal milling plays a vital role in the manufacturing industry. The process involves using automated tools to cut and shape materials into precise shapes and sizes, making it an efficient method for producing complex parts. However, not all CNC milling services are created equal. This page will explore the differences between 3-, 4-, and 5-axis CNC milling and why it matters to you. We will cover everything from the basics of CNC milling to the comparative analysis of capabilities and cost comparison. You will learn about the benefits and challenges of each type of milling and gain insight into which milling process will affect your parts. Additionally, we will discuss how these different types impact manufacturing speed and finished product quality. With our help, you can make informed decisions about your CNC milling needs and choose the right service to ensure your projects succeed.

What is CNC Milling and How Does it Work?

CNC milling is a manufacturing process that uses computer-controlled machines to remove material from a workpiece to create a desired shape. It works by using rotating cutting tools to carve into the material and follow specific instructions programmed into the machine’s computer system.

The Basics of CNC Custom Metal Milling

CNC custom milling uses a process known as computer numerical control milling, which uses computer programming to guide the milling machine in removing or subtracting material from a solid block. The cutting tool of the machine moves along multiple axes, enabling the creation of intricate and exact shapes. Industries such as aerospace, automotive, and medical frequently utilize this service due to the high-quality, precise components it can produce within strict tolerances. The advantages of using a CNC milling service from our company over manual machining methods include increased efficiency, cost savings, and faster production speeds.

Importance of CNC Milling in Manufacturing

Custom metal milling plays a crucial role in the manufacturing industry, offering precise and efficient production of complex parts through the use of cutting-edge technology, including machine tools. This process has revolutionized the industrial world by significantly reducing production times and costs. It’s widely utilized in industries such as aerospace, automotive, medical, and electronics. With advancements in technology, CNC machines have become more versatile, providing greater precision and flexibility for various milling and CNC turning jobs. As the manufacturing industry evolves, the importance of CNC milling and turning services, including machine tools, will continue to grow.

Difference Between 3-, 4-, and 5-Axis CNC Milling

3-axis milling is the most basic and commonly used method of milling parts. It involves the spindle cutting along three axes: X, Y, and Z. 4-axis milling, on the other hand, adds a rotary axis to one of the existing three on a 3-axis machine. This allows for more complex shapes to be created as the part can be rotated during CNC machining. However, 5-axis milling is considered the most advanced form of CNC milling machining services as it adds a second rotary to yet another axis on a traditional 3-axis machine. This enables even more complex shapes to be produced with greater precision and accuracy. With 5-axis milling, manufacturers can create complex geometries and intricate designs that would otherwise be impossible with other methods. This custom CNC milling technique is used extensively in various industries such as aerospace, automotive, medical devices, and more.

Comparative Analysis of Capabilities

Understanding the different types of machines offered by a CNC milling company can improve the manufacturing process and result in easier and cheaper production of parts. The choice of machine for CNC milling depends on the part’s features, which impacts the quality and cost-effectiveness of the final product. Factors like speed, precision, and complexity determine the best-suited machine for a specific part. By understanding the capabilities of 3-, 4-, and 5-axis machines, we’re not only able to optimize part features and meet customer expectations, but also maximize the value of using CNC milling services.

Cost Comparisons

When it comes to cost, different types of CNC milling offer varying options. 3-axis is the most cost-effective for simple parts and prototypes. As you move to 4-axis milling, the costs increase due to the addition of rotational movement for more complex shapes. For the highest precision and flexibility in intricate designs, 5-axis milling is the way to go. However, this precision comes at a higher cost. Ultimately, the choice depends on the complexity of the part features.

SMF Will Determine Which CNC Milling Type Is Best for Your Parts

There are hundreds of factors that help us determine which machining process is best suited to produce your parts. Things like quantity, material, and part geometry are just a few. As a CNC milling company, we also must think about how to minimize setup and multiple operations for our CNC milling services. Streamlining these steps allows us to pass the cost savings on to you. So, the point of this page is to help you understand that the design of the part can change the per-piece price considerably. Don’t design a 5-axis part when a 3-axis part will do!

Overview of 3-Axis CNC Milling Machines

An in-depth overview of 3-axis custom CNC milling explores the differences between 3-, 4-, and 5-axis machines. While 3-axis machines are suitable for simple parts and projects without complex shapes or features, they have advantages and limitations to consider. The best applications for our 3-axis CNC milling services include basic designs and projects that require precise parts. However, it may not be the best choice for intricate geometries. Understanding the capabilities and limitations of 3-axis CNC milling helps to make informed decisions.

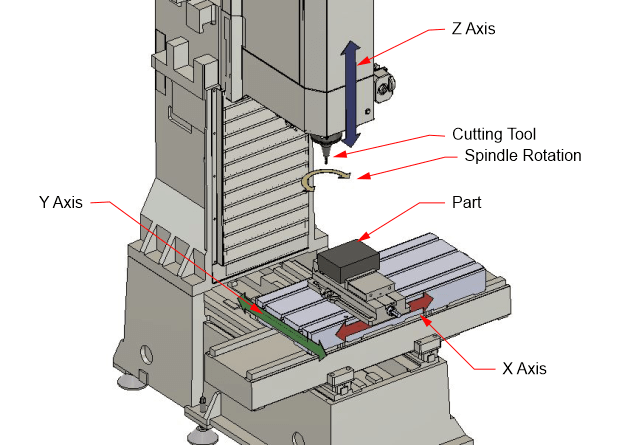

What Is 3-Axis CNC Milling?

3-axis CNC milling, also known as 3-axis machining, is a type of CNC machining that utilizes three axes: X, Y, and Z. It is the most basic form of milling and is commonly used for creating simple parts with flat surfaces. The process is automated and controlled by computer software, allowing for quick and accurate production. However, 3-axis machining does have limitations when it comes to creating complex shapes. Despite this, this type of CNC milling service remains a cost-effective option for projects that require simple parts. Talk to our CNC milling company to discuss your project requirements.

Benefits and Challenges of 3-Axis CNC Milling

3-axis CNC milling is widely used in industry and DIY projects. It’s ideal for simple shapes and flat surfaces, producing high-quality results with precision and accuracy. However, its use for more complex designs can be limited. At Schantz Machine & Fabrication, we have the experience to manage the correct process for producing your parts, ensuring that you get the best possible outcome. Trust us with your 3-axis CNC milling needs.

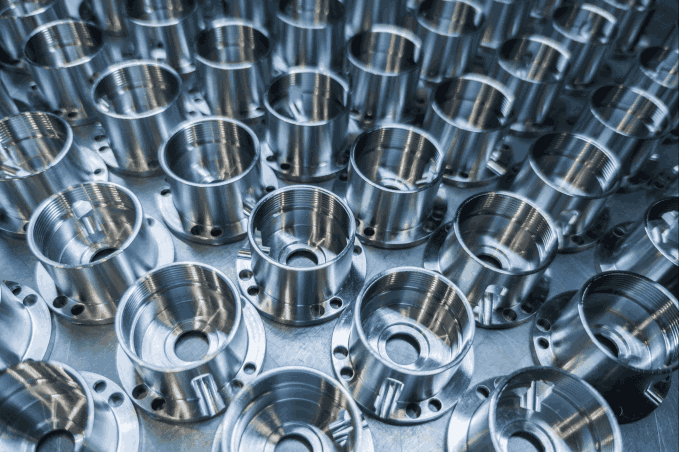

Examples of 3-Axis CNC Milling Parts

This type of custom CNC milling service is ideal for producing less complex parts, allowing for faster manufacturing and lower costs compared to more intricate designs. The process involves cutting tools moving along three linear axes (X, Y, and Z) to shape the part. Some examples of parts that can be produced through 3-axis milling include brackets, plates, and frames. Understanding the distinction between 3-axis and angled feature machining is important when designing parts for CNC milling. An angled feature is a feature machined on an angle to one of the X, Y, or Z axes.

Can 3-Axis CNC Milling Create 3D Style Parts?

Yes, 3-axis CNC milling can create 3D-style parts. However, this type of CNC milling service has limitations in accessing certain angles and contours, making it unsuitable for manufacturing some types of features at an angle to the X-Y-Z coordinate system. For more flexibility and precision in creating complex shapes, our CNC milling company recommends 4- or 5-axis machines. The choice of technique depends on the specific part being produced and whether a 3-axis machine can handle the required features.

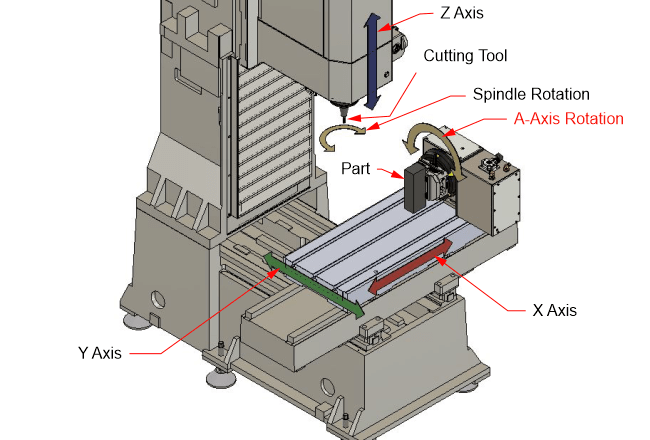

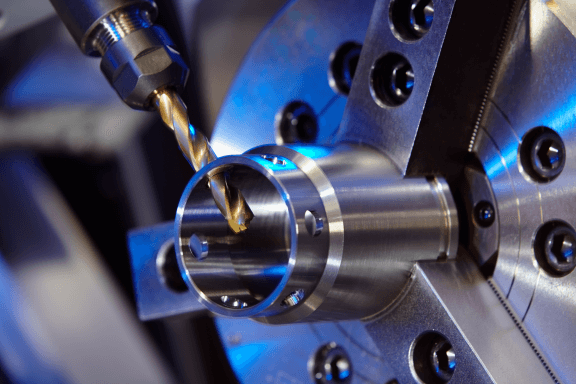

4-Axis CNC Milling: CNC Cutting Enhanced

A 4-axis CNC milling machine has the traditional X, Y, and Z coordinate system but also has an additional A axis. It differs from both 3-axis and 5-axis milling in terms of its capabilities. The main advantage of 4-axis milling over traditional 3-axis CNC milling service is the ability to rotate the part being machined. This enhances the flexibility and precision of the custom CNC milling process, allowing for the creation of more intricate geometries and precise parts. Industries such as aerospace, automotive, and medical can benefit greatly from 4-axis CNC milling technology. At SMF, our team will consider the pros and cons of 4-axis CNC milling to determine if it’s the right choice for your parts.

Benefits and Challenges of 4-Axis CNC Milling

4-axis CNC milling offers increased flexibility and precision when machining complex surfaces, improving overall efficiency by reducing multiple operations. However, it also presents challenges like the need for specialized tooling and programming skills. It’s crucial to consider these benefits and challenges before choosing 4-axis CNC milling services for the parts to be quoted. Ultimately, the decision between 3-, 4-, or 5-axis milling depends on the specific geometry and precision required. SMF has 4-axis milling capabilities on most of its machines, along with the skills to program them quickly.

Examples of 4-Axis CNC Milling Parts

Enhanced versatility and precision are the hallmarks of 4 Axis CNC. By adding a rotational function, the 4th axis, opens up possibilities for machining intricate geometries. Gears, propellers, and turbine blades are just some examples of components that benefit from 4 Axis CNC milling. Industries such as aerospace, automotive, and medical rely on this technology for its ability to produce precise parts. While costs may be higher than 3 axis milling, the advantages of less set-ups and faster run times usually out-weigh the cost of running parts on a more expensive machine.

5-Axis CNC Milling: The Ultimate for Aerospace!

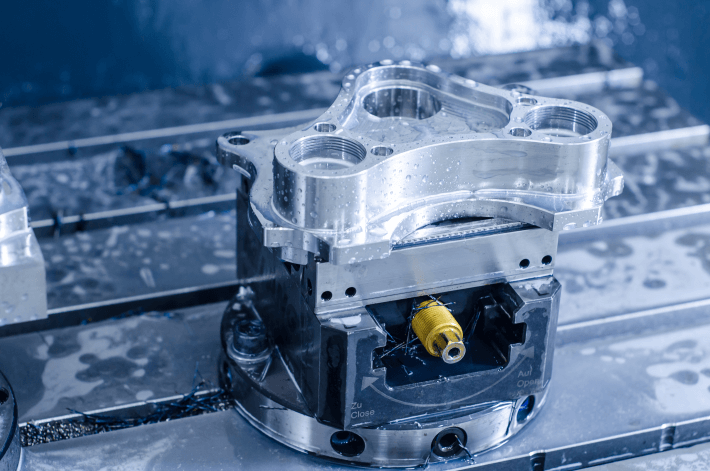

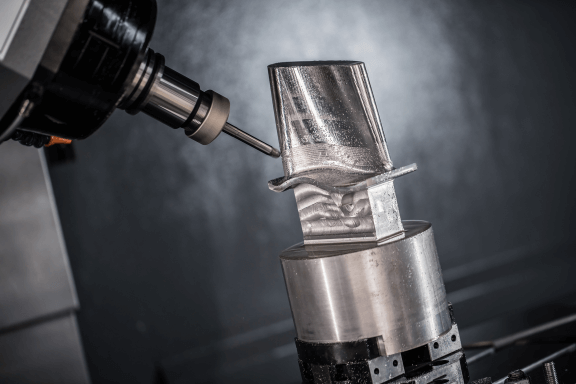

5-axis CNC milling takes precision and accuracy to the next level. It allows for machining from multiple sides in one setup, making it perfect for complex geometries and intricate designs. With reduced need for additional setups, this custom CNC milling method is commonly used in industries that demand high-quality surface finishes.

What is 5-Axis CNC Milling?

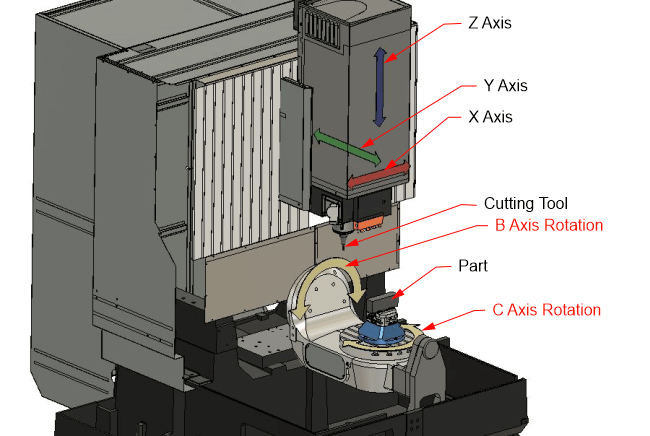

5-axis CNC milling, also known as 5-axis machining, involves the simultaneous movement of the workpiece along five different axes, resulting in fewer operations and higher accuracy. With three linear axes (X, Y, Z) and two rotational axes (B and C), this type of CNC milling service allows for cutting from almost any angle. The ability to tilt and rotate the mill table enables the machining of complex geometries all in the same operation. This eliminates the need to manually reposition the workpiece between operations. Every time a workpiece or part needs to be repositioned, it’s possible to lose accuracy.

Applications of 5-Axis CNC Milling – Automation and Workpiece Accuracy

The applications of 5-axis CNC are diverse and crucial in various industries. In the aerospace industry, 5-axis CNC milling plays a vital role in manufacturing turbine blades with intricate geometries. The medical industry relies on this machining process to produce precise parts for medical equipment. Automotive manufacturers benefit from 5-axis CNC milling services as it allows them to create complex components. Additionally, industries such as defense and electronics, which require high precision, utilize 5-axis CNC milling for its accuracy and ease of automation. Our CNC milling company is at the forefront of these machining solutions.

Benefits of 5-Axis CNC Milling

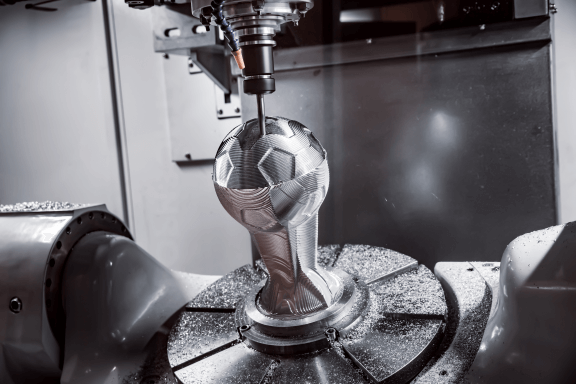

The pros of 5-axis CNC milling include increased efficiency and reduced setup time. This type of machining allows for the production of complex parts in a single setup, improving workflow and saving time while increasing accuracy. However, there are challenges to consider. 5-axis milling machines are more expensive and require advanced programming knowledge. Despite these challenges, there are notable benefits of this custom CNC milling method, such as improved accuracy and surface finish compared to lower-axis machines. Additionally, the versatility of 5-axis CNC milling services allows for the production of parts with complex geometries.

Examples of 5-Axis CNC Milling Parts

5-axis milling finds extensive use in the aerospace industry for manufacturing precise and intricate parts with complex geometries like impellers and turbine blades. Medical devices and implants also benefit from the precision provided by 5-axis CNC milling. Additionally, this type of milling is employed in the production of molds and prototypes with intricate shapes. Industries such as automotive and defense, which require high-quality surface finishes, also rely on 5-axis machining. In the aerospace industry, a machine like the Haas UMC-750 is used to build parts for commercial and military avionics. With this machine, manufacturers can machine five sides of the part, allowing them to achieve the necessary dimensions and complexity. This is a core part of our 5-axis CNC milling service.

Why Choose Schantz Machine & Fabrication (SMF)?

Our experts are available by phone to discuss design for manufacturing (DFM), finishing specs, and anything you need to help achieve high-quality CNC milling machine services. Whether you need a single prototype or a multiple-item production order, our CNC milling company is here to help.

CNC milling services are just one of the ways that we can help you. If your parts require additional services like plating, anodizing, or heat treating, we can handle that too.

At SMF, we invest in the latest custom CNC milling technology. We have 3-, 4-, and 5-axis CNC milling centers to make nearly anything you can imagine. Our quoting and collaboration tools streamline the procurement process. We utilize the latest CAD/CAM software to handle the file types you like to work with.

Low-Volume CNC Machining

Contact Us

Home » CNC Machining » CNC Milling

How Can We Help You Today?

From initial design to prototypes and full production, you can count on us to deliver quality parts on time and on budget!