Schantz Fabrication

CNC Machining Services

High-quality CNC machining with fast turnaround times and no minimum orders. We’re Schantz Machine & Fabrication, your partner bringing expertise and quality control for projects from simple parts to complex multi-part RFQ’s.

Why Partner with Us?

For over 60 years, Schantz Machine & Fabrication (SMF) has specialized in CNC machining and custom fabrication services for highly customized and precise parts. Our expertise in rapid prototyping, stringent quality control, professional design for manufacturing, and low-volume production with no minimum orders positions us to handle big projects for parts in the tens of thousands, or custom jobs as small as a single unit. Our team’s expertise in CNC machining and fabrication services ensures consistent delivery of high-quality custom parts, outstanding service, and schedule-oriented delivery.

This makes us the go-to CNC machining company when you need quick production of prototypes and proof-of-concept parts with short lead times. Whether your project demands intricate detailing or robust production, we tailor our approach to meet your custom CNC machining & fabrication specifications with precision and care.

Industries We Serve

Robotics & Automation

Trailer & Agriculture

CNC-machined parts for trailers and the agriculture industry increase efficiency, accuracy, and precision to improve performance and reliability.

Pneumatics & Hydraulics

CNC machining services such as turning and milling create components that meet the exacting needs of the pneumatics and hydraulics industries.

Food & Beverage

With CNC technology, food and safety equipment is precision-engineered, essential to maintaining sanitary conditions in processing plants.

Automotive

CNC-machined parts in the automotive industry allow for precise alterations or adaptations to a wide range of automotive parts.

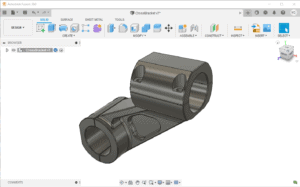

Design for Manufacturability

Utilizing the latest solid modeling and programming software, Schantz Machine & Fabrication integrates design-for-manufacturing (DFM) principles to streamline the journey from concept to creation. This approach reduces prototyping time and minimizes production costs, ensuring your parts are designed for optimal manufacturability and cost-efficiency. Our expertise in CNC machining and fabrication services enables us to refine your designs for maximum functionality and economy.

Precision Quoting

Our advanced quoting software for CNC machining services stands out by instantly spotting manufacturability issues, streamlining the production process, and preventing costly revisions. This proactive approach saves time and money and ensures a smooth transition from design to production. At Schantz Machine & Fabrication, we prioritize efficiency and accuracy in quoting and provide reliable and transparent cost assessments.

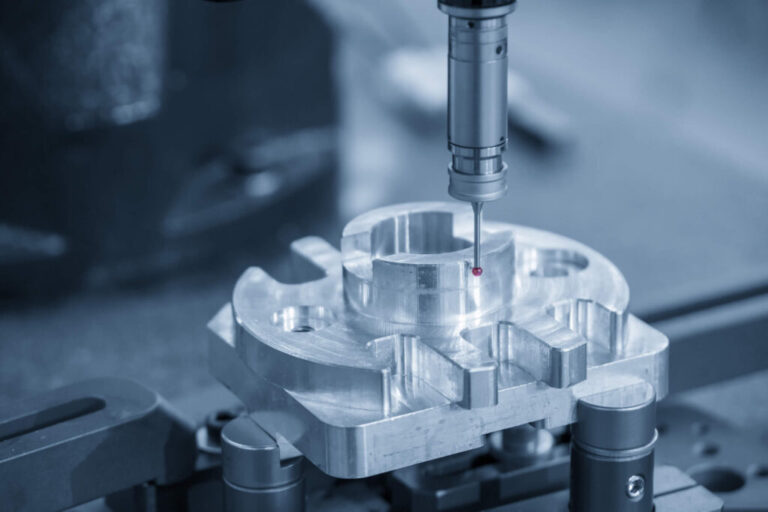

Advanced Manufacturing

Our modern CNC machinery, equipped with cutting-edge tooling and optimized processes, is at the heart of our custom CNC machining and fabrication operations. This setup ensures we consistently produce high-quality parts that meet tight tolerances with utmost efficiency. Every piece, from the first to the last, adheres to the highest standards of precision and quality.

Stringent Quality Control

Rigorous quality control standards underpin our commitment to excellence in CNC machining services. These standards guarantee that every part we produce, regardless of the batch size, is flawless and meets your exact specifications. Our quality assurance processes are designed to ensure that each part from Schantz Machine & Fabrication is a benchmark of excellence in the industry.

Comprehensive Finishing

Our strategic partnerships for specialized finishing services include heat treating, plating, and powder coating. These collaborations, combined with our commitment to achieving the perfect surface finish, simplify your part-sourcing challenges. We ensure that every component produced through our CNC machining services not only meets functional requirements but also exhibits aesthetic excellence.

Strategic Inventory Management

Our innovative inventory management system, including a reserve inventory option (KanBan), is designed to mitigate risk and ensure supply stability. By maintaining a stock of your critical parts, we can swiftly meet sudden increases in demand, ensuring that your production lines keep moving without interruption. Expect responsive CNC machining and fabrication services to support your business’s dynamic needs.

Discover the Difference With Schantz Machine & Fabrication

With decades of expertise in CNC machining services, we cater to various industries, including automotive, manufacturing, oil and gas, food and beverage, and government sectors. Thanks to our advanced programming and milling capabilities, our strength lies in efficiently accommodating low-volume orders, even as low as a single unit. This approach ensures cost-effective and timely production for any order size.

Unlike the transactional nature of industrial sourcing giants, Schantz Machine & Fabrication (SMF) treats you as more than just an order to fill. We see ourselves as an integral extension of your team, committed to the success of your projects. Our CNC machining services workshop prioritizes client-centric service, offering personalized solutions and dependable support regardless of the project scale. Our rapid CNC machining and design consultants are here to help you get started.

What Schantz Machine & Fabrication Customers are Saying

Our Goal is to Help Our Customers Thrive

At SMF, we’re dedicated to empowering your success by delivering high-quality custom CNC machined parts. With our collaborative design process, advanced technology, and streamlined production processes, we ensure you receive unparalleled value and quality for CNC machining services.

Adaptable Production for Every Need

Our expertise lies in low-volume production, specializing in runs of 5 to 500 pieces. Our refined processes and vast industry experience enable us to deliver all types of parts across various scales and needs. Recognizing the diverse demands of projects, we’re one of the most established and flexible online CNC machining services, catering to both large and small orders. Our KanBan inventory system ensures a ready supply of your parts, providing stability even in fluctuating demand scenarios.

With over 60 years of experience, SMF has provided high quality machine and fabricated parts for customers across a wide range of industries including motorsports, OEM manufacturing, food and beverage, as well as various government subcontractor supply chains.

Our CNC machining is performed using state-of-the-art equipment, ensuring superior accuracy and precision in your parts. Plus, our team of expert fabricators will help to ensure a perfect fit and finish in all your production runs.

SMF is a family-owned and operated cnc machine shop near St. Louis, that takes immense pride in its highly skilled employees who possess extensive knowledge and experience in precision CNC machined parts and fabrication. This expertise allows them to produce high-quality machined and sheet metal products that meet the needs of their clients. SMF’s commitment to excellence has helped them build a reputation as a trusted partner, delivering custom metal parts that exceed customer expectations. With their focus on quality, innovation, and customer satisfaction, SMF is poised for continued success in the industry.

Advantages of Our Integrated Approach to CNC Machining Operations

- Customization: We excel at crafting highly precise parts tailored to your exact specifications. Our integrated CNC machining and fabrication services allow us to handle your project from start to finish, ensuring a seamless and comprehensive solution.

- Flexibility: Our custom CNC machining and fabrication capabilities enable us to quickly adapt to your needs, whether you require a small batch or large-scale production. With our robust inventory management system, we guarantee the availability of your parts, providing them precisely when you need them. This ensures the continuity of your project without delays.

- Quality Assurance: We leverage our industry expertise to uphold the highest quality standards. Our seasoned approach to CNC machining and fabrication is reflected in the end products we deliver to our clients, affirming our commitment to project accuracy.

Schantz Machine & Fabrication News & Information

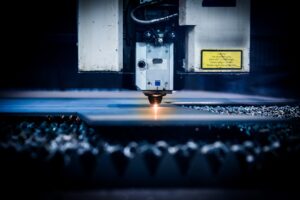

What Is CNC Laser Cutting?

What Is CNC Laser Cutting? Precision and efficiency are paramount when it comes to manufacturing and fabrication. It is for these reasons that the manufacturing

Titanium vs Steel Choice

Titanium vs Steel: Whats the Better Choice? In the manufacturing world and the machining industry, titanium and steel are the top choices when it comes

Top Challenges to Consider When Machining Titanium

Top Challenges to Consider when Machining Titanium Titanium’s high strength, high corrosion resistance, low weight, and other distinctive characteristics make it a material that is

What is Turning CNC Turning Milling for Custom Machining

What is Turning? CNC Turning & Milling for Custom Machining CNC machining encompasses several processes, the outcomes of which can include tools, parts, or components

What is a Custom Fabrication Shop a Review of Our Capabilities

What is a Custom Fabrication Shop? : A Review of Our Capibilities The Schantz family began building custom trailers and trucks for the food industry

How to Keep Costs Down with Low Volume Production Machining

How to Keep Costs Down with Low Volume Production Machining The biggest hurdle when it comes to low-volume production machining is the per-unit cost. This

Talk To A CNC Design Consultant About Your Project

Ready to get started with our CNC machining services? Talk to one of our CNC machining and fabrication experts at SMF to help you navigate your project requirements, from initial design through prototyping to full-scale production. You can count on us to deliver high-quality parts on time and on budget.

Upload your design file for a free, detailed quote on production costs within 24 hours.