What is Turning? CNC Turning & Milling for Custom Machining

CNC machining encompasses several processes, the outcomes of which can include tools, parts, or components for use in almost every industry. Boring is the process of removing material from the inside of a rotating piece, while turning removes material from the outside. The process of turning is achieved using tools such as CNC lathes.

Utilizing processes like CNC turning and milling near St. Louis, MO, Schantz Machine & Fabrication (SMF) is a valued and reliable source of custom metal fabrication, metal manufacturing, structural metal, welding, prototyping, fixturing, and low volume production machining. For more than 60 years, SMF has taken customers’ drawings, blueprints, and ideas, fabricating them into functional and productive pieces that meet exact tolerances and specifications.

What is CNC Turning?

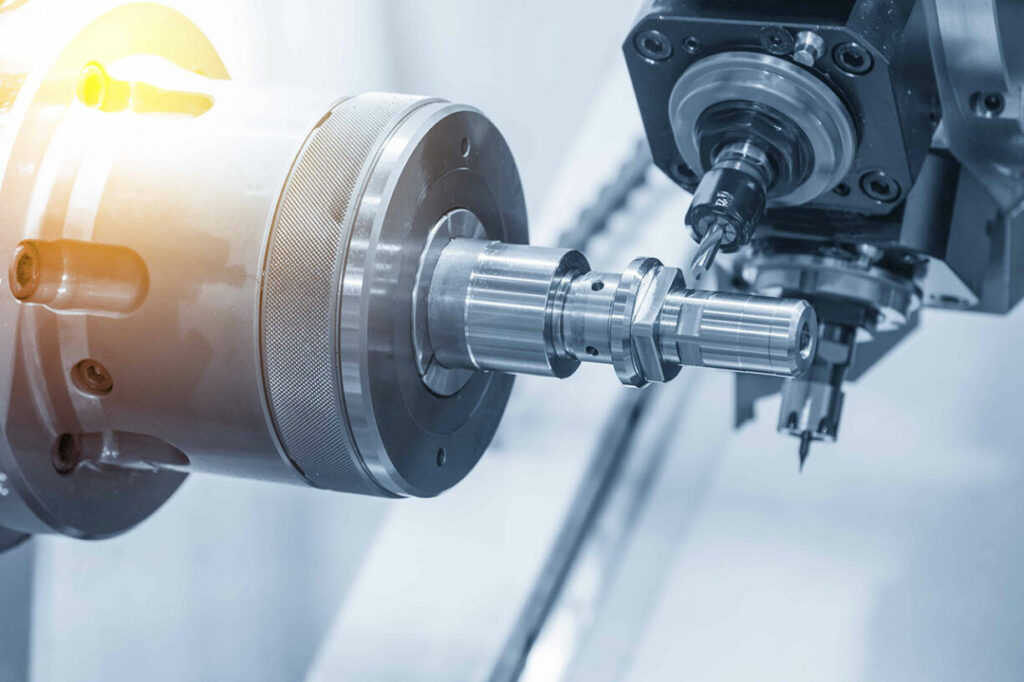

CNC turning and milling is the process of using CNC lathes and other tools to remove material from the outer diameter of a rotating workpiece. Single-point tools shave excess metal from the workpiece, typically in small, easily recyclable chips.

Operated with Computer Numerical Control (CNC) systems and provided with precise design instructions, CNC lathes are machine tools where the source material is clamped and rotated by the main spindle, while the cutting tool that works on the material is mounted and moved in various axis. The rotating action of the part is called “turning,” and as a result, certain types of CNC lathes are referred to as CNC turning machines. CNC lathes feature a constant surface speed control, enabling the operator to select a precise speed. The CNC lathe automatically adjusts the RPM as the cutting tool moves along the outer profile of the workpiece.

CNC turning and milling near St. Louis – and other sections of the country – is a combination of linear (tool) and rotational (workpiece) movement. Thus, cutting speed is defined as the rotational distance traveled in one minute by a point on the part surface, recorded as either surface feet per minute or square meters per minute. Feed rate (recorded in inches or millimeters per revolution) is the linear distance that the tool travels along or across a workpiece surface. Feed rate requirements vary depending on the application. For example, in roughing, high feeds are generally better for maximizing metal removal rates, but also require high part rigidity and machine power. On the other hand, finish turning could slow the feed rate to produce the surface finish specified for the individual part.

CNC lathes, and specifically CNC turning, often constitute several, and often complex, stages of the part manufacturing process. They frequently eliminate the need to transfer the part to another machine for additional operations.

How Schantz Machine & Fabrication

Utilizes CNC Turning and Milling

Schantz Machine & Fabrication utilizes processes like CNC turning and milling near St. Louis as part of the custom metal fabrication process. With experience and capabilities spanning a wide variety of industries, SMF most commonly machines parts for commercial trucking, service trucking, trailer trucking, and the motocross and racing industries.

SMF specializes in low-volume production machining services. At many other shops, these types of orders are very costly because creating a part program and preparing a mill or lathe for a job takes equally long if one part is being machined or 1,000 parts. SMF resolves these issues by efficiently and affordably minimizing cycle times with high-speed machining. The shop is organized and workflows designed to set up every job in the shortest possible time. Additionally, Schantz Machine & Fabrication maintains CNC machine tools to ensure they cut quickly and accurately. They are better positioned to handle small-quantity production because they invested time and effort into driving down the time spent on “non-productive” activities.

A one-stop-shop for all types of custom metal fabrication needs, from in-house design services to full prototyping potential and beyond, Schantz Machine & Fabrication’s precision machining and milling capabilities extend to working with titanium and crafting titanium machine parts. For performance parts and more, SMF can utilize titanium machining and milling for the exotic automobile, commercial trucking, diesel trucking, and motorsports industries, among others.

Prototype machining near St. Louis is one of the most frequently requested types of machining offered by SMF. Using CNC turning and milling along with sheet metal material, SMF produces functional, production-quality prototypes. Schantz is also capable of a broad range of machining types, including high-speed machining and milling, cutting-edge technology (such as AutoDesk programs, AutoCAD, and Solidworks), and the ability to complete projects on time and on budget.

Custom Machining Services Near St. Louis

Schantz Machine & Fabrication offers a wide range of services, including structural fabrication, tubing, custom fixture design and production, and functional prototyping. We have extensive experience with CNC machining, and we’re experts at using CNC turning and milling to produce complex precision parts in St. Louis. When it comes to machining parts, we’re the team to trust

Other Articles of Interest

Titanium vs Steel Choice

Titanium vs Steel: Whats the Better Choice? In the manufacturing world and the machining industry, titanium and steel are the top choices when it comes

Top Challenges to Consider When Machining Titanium

Top Challenges to Consider when Machining Titanium Titanium’s high strength, high corrosion resistance, low weight, and other distinctive characteristics make it a material that is

What is Turning CNC Turning Milling for Custom Machining

What is Turning? CNC Turning & Milling for Custom Machining CNC machining encompasses several processes, the outcomes of which can include tools, parts, or components

How Can We Help You Today?

From initial design, to prototypes and full production,

you can count on us to deliver quality parts,

on time and on budget!