CNC Rapid Prototyping Vs. 3D Printing

- Posted By: Zach Schantz

When you have a great product idea, it’s natural to want a part in your hand as quickly as possible. This allows you to look at the product, test it, and see if it will fit where it’s meant to be. Of course, most designs require some degree of tweaking; you’ll probably go through a few iterations before getting exactly what you need. The faster you receive your prototypes, the quicker you can get to market. Unfortunately, there’s a belief in some quarters that rapid prototyping is just another term for 3D printing. We’d like to compare CNC machining and rapid prototyping with 3D printing and explain why CNC machining is the faster prototyping process.

Understanding the 3D Printing Process -

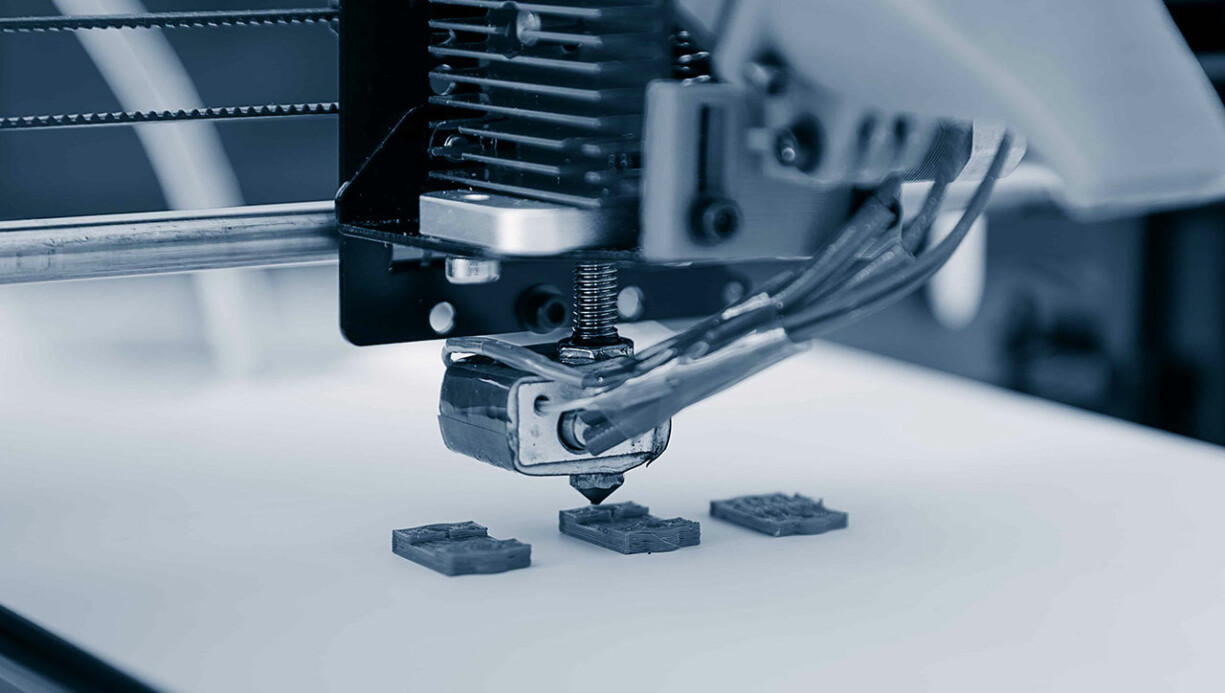

3D Printing for Prototyping

A 3D printer may be many things, but if you’ve ever watched them work, you’ll know that “rapid” isn’t one of them. Building a 3D part layer by layer can take hours, and it doesn’t stop with the actual printing. A CAD model isn’t enough to get started; you have to add support structures so the part doesn’t collapse. Then, once it’s printed and you’re happy with the part, additional cutting is required. Most printing processes leave layers visible on the surface, so you can plan on grinding or sanding them off, too. All in all, 3D printing is suitable for some prototypes, but also faces a number of limitations.

Material Limitations of

3D Printing

Metal printing is evolving quickly, but these processes are limited by the need to deposit and fuse a powder. This means you may not be able to have a part 3D printed in the exact material you want. That can have implications for testing and appearance.

Size Limitations of

3D Printing

Most 3D printers on the market today have a working envelope no bigger than a shoebox. Yes, there are some larger machines, but unfortunately, they carry large price tags, too! Comparatively, most CNC lathes and mills offer much larger envelopes.

CNC Machining is More Accurate than 3D Printing

CNC machining is extremely accurate. We can hold tolerances as tight as +/- 0.05mm (0.002″). Fused deposition modeling, (FDM – the plastic extrusion process), achieves about +/- 0.5mm. Selective laser sintering (SLS) is around +/- 0.35mm.

CNC Rapid Prototyping VS. 3D Printing for Your Parts and Components

High-speed machining is just that: high-speed. With the CNC machining techniques and machine tools we use, we can go from a CAD model to a machined part in just a few hours. In fact, we are sometimes able to complete it faster depending on the size and complexity of the part.

Benefits of CNC Rapid Prototyping

- Your part machined in the exact material you want

- A part suitable for functional testing

- Final part precision, meaning it will be made to print and will assemble to mating parts

When is 3D Printing Right for Prototyping

- You just need a low-fidelity part to hold in your hand.

- You would be machining away most of the material.

- You need features that can’t be produced by machining.

Schantz Machine and Fabrication Offers

Rapid Prototyping Solutions

More often than not, CNC rapid prototyping can be a faster and more efficient method than 3D printing. If you need prototype parts in a hurry, bring your design to us and we’ll tell you what we can do. Contact Schantz Machine & Fabrication to get started on your CNC rapid prototyping project today.

Other Articles of Interest

Titanium vs Steel Choice

Titanium vs Steel: Whats the Better Choice? In the manufacturing world and the machining industry, titanium and steel are the top choices when it comes

Top Challenges to Consider When Machining Titanium

Top Challenges to Consider when Machining Titanium Titanium’s high strength, high corrosion resistance, low weight, and other distinctive characteristics make it a material that is

What is Turning CNC Turning Milling for Custom Machining

What is Turning? CNC Turning & Milling for Custom Machining CNC machining encompasses several processes, the outcomes of which can include tools, parts, or components

How Can We Help You Today?

From initial design, to prototypes and full production,

you can count on us to deliver quality parts,

on time and on budget!