Custom CNC Machining

Schantz Fabrication

Schantz Machine & Fabrication provides custom CNC machining in the St. Louis area and the entire United States.

We can create custom CNC parts with complex geometries that require 3, 4, and 5-axis milling or Y-axis lathe work with no minimum order volume.

A Full-Service CNC Machine Shop For CNC Milling and Turning

Finding a reliable metal machining shop that offers comprehensive CNC milling and turning services is vital for complex and precise custom machine parts.

Skip the frustration of coordinating between different shops to complete your project. Schantz Machine & Fabrication (SMF) is your one-stop solution, offering full-service CNC milling and turning capabilities. We can handle your custom CNC machining project from start to finish, regardless of its complexity.

3, 4, and 5-Axis Milling

Manufacturing parts with complex geometries and tight tolerances can be a significant challenge. Most CNC machining shops require longer lead times and higher costs for these orders. At SMF, we utilize advanced 3, 4, and 5-axis milling processes that enable us to create custom prototypes and custom-produced CNC parts much quicker, and at lower costs.

Our sophisticated milling capabilities allow us to produce parts with complex features and dimensions in a single setup, reducing production time. Our custom CNC machining expertise ensures that we can meet tight tolerances and produce high-quality, precise parts efficiently.

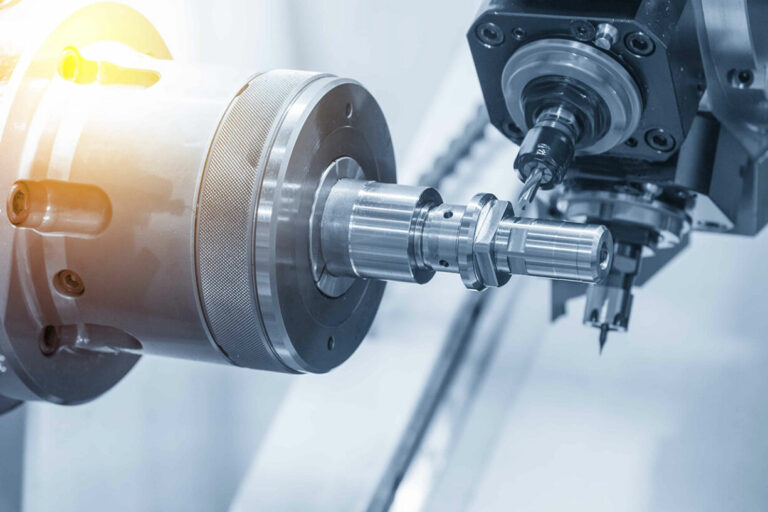

CNC Turning (Y-Axis)

Producing parts with complex features such as axial and radial holes, flats, grooves, and slots can also be challenging. Our CNC machining shop addresses these challenges with live tooling and Y-axis capabilities.

This custom CNC machining technology allows us to perform turning and milling operations in a single setup, enhancing the efficiency and accuracy of producing parts with complex features. Our CNC lathes with Y-axis capability ensure we can quickly and accurately produce parts with the required axial and radial holes, flats, grooves, and slots, reducing lead times and costs while maintaining high-quality standards.

Quick Prototypes & Production Runs

We specialize in quick-turn prototypes and extensive production runs and can handle a wide range of projects. Our machining expertise extends from straightforward 3-axis parts to intricate designs necessitating 5-axis precision.

Our state-of-the-art lathes enable us to efficiently manufacture custom CNC parts with complex, off-center features. We comply with ISO 9001:2015 standards, underscoring our commitment to quality and ensuring that every part we produce at our CNC machining shop meets the highest standards of excellence.

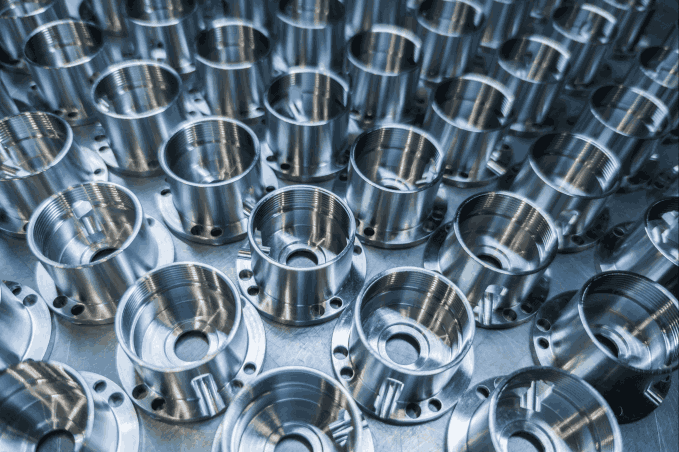

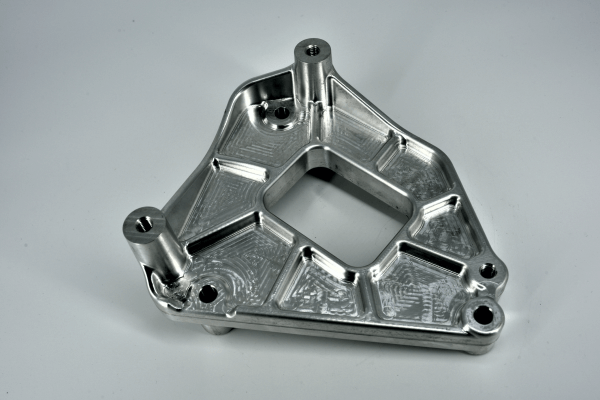

Examples of Our CNC Machine Shop Parts

Our CNC machine shop is proud to showcase a gallery that represents the diverse range of custom parts we’ve produced through our advanced steel, titanium, or aluminum CNC machining services. This collection highlights the versatility and precision of our custom CNC machining capabilities, featuring examples from various industries and applications. Whether you want to see examples of our aluminum CNC service or plastic machining service, each custom CNC part in the gallery exemplifies our commitment to quality and our ability to meet the unique specifications and demands of our clients.

SMF Common CNC Machine Shop Materials

Schantz Machine & Fabrication offers a wide range of materials to satisfy your prototype and production needs.

Metal CNC Machining Materials

2011 – free machining, used for connectors, fittings, and computer parts.

2024 – Considered “aircraft” aluminum, good for rolled threads and hydraulic valve bodys.

6061 – Good weldability, considered a “general” alloy its good for most all structural type parts.

6063 – Also good weldability, but not as strong as 6061

7075 – noted as the strongest and hardest alloy, good for high strength parts, preferred by the aircraft industry.

260 – known as cartridge brass or yellow brass, used for ammunition, engraving, and decorative furniture parts.

360 – utilized in general screw machine applications, typical applications include: plumbing products, fittings, adapters, valve stems.

932 – high leaded, known as bearing bronze because it is often an ideal choice for bearing applications.

954 – aluminum family of bronze, good for gears, bushings and wear strips and plates.

110 – high electrical conductivity, used in electrical components.

145 – Typical applications include, electrical connectors, motor parts, plumbing fittings, and torch tips.

303 – easily machinable with good corrosion resistance, used for shafts, gears, aircraft parts.

304 – Superior corrosion resistance, weldable, used in food processing equipment, springs, and kitchen equipment.

316 – used in parts that require resistance to chemical corrodents, and marine applications.

410 – not recommended for applications in which severe corrosion is encountered, can be hardened for high strength parts.

416 – is a free machining stainless good for high temp parts like pump parts, shafts, studs and gears.

420 – contains more carbon for improved strength and toughness, good for high wear parts like bearings, shear blades, and surgical instruments.

440C – with more carbon than 420, 440C is good for parts like knife blades and chisels.

A-36 – excellent for welding and forming, used for machinery parts, frames, and structures.

1018 – easy to form, weld and machine, good for basic steel parts.

1045 – stronger than 1018, not good for welding, but machines to a nicer finish than 1018. Good for shafts, axles, and crankshafts.

1117 – a low carbon, high manganese steel, good for case hardening and parts that need carburizing treatments.

12L14 – low friction for machinability which produces an excellent finish, used in screw machine parts like bushings and couplings.

Grade 2 – moderate strength, used a lot in power generation for parts like shrouds and covers.

Grade 5 (Ti 6Al-4V) – the most popular grade of Titanium and used in the aerospace industry for engine parts and also for parts like sports equipment and biomedical parts.

SMF can source and provide other types of material grades not listed here. Please ask a SMF representative for help with material selection along with your custom CNC machining service.

Plastic CNC Machining Materials

Acetal plastics provide a low coefficient of friction and good wear properties. Available in several variations, 1 of which with a trade name of Delrin.

Acrylic is completely transparent and good for glass replacement applications. Its also impact resistant, lightweight, weather resistant and heat resistant.

ABS, is a low cost plastic that machines easy. It is an ideal material for applications when low cost, strength, and stiffness are required. It can be painted and glued which is why it is widely used for prototype work.

is a formable almost clear plastic used widely in the packaging industry. Also used in indoor signs and displays. Comparable to polycarbonate but with lower cost.

Popular cutting board material HDPE is easy to machine, impact resistant and resists abrasion. Used for parts like cams, shims, and bushings.

Offered in several different variants, Nylon is one of the most widely used thermoplastics. Its FDA, USDA, NSF, 3-A Dairy Compliant, which makes a good choice for general machined parts in these industries.

The UHMW family, also known as high-performance polyethylene, has the highest impact strength of any thermoplastic presently made. It has a very low coefficient of friction and is self lubricating. It also machines well and is available in many variants making it good for parts in many different industries.

With to many plastics to list here, SMF can source and provide many other types of materials. Please ask a SMF representative for help with your material requirements.

Why Choose Schantz Machine & Fabrication’s CNC Machining Services?

Schantz Machine & Fabrication (SMF) stands out from larger industrial sourcing marketplaces like Xometry, Protolabs, and Hubs.com by offering a personalized approach to custom metal machining services. Our focus on individualized service ensures that we understand and meet the specialized needs of our clients with greater flexibility and attention.

Added Benefits Include

Design for Manufacturing (DFM)

We employ DFM strategies to create custom CNC machining products that are easier and more cost-effective to manufacture. By optimizing the design process, we minimize manufacturability issues, enabling faster production with commonly available tools, which in turn reduces costs.

Uncompromising Quality

At SMF’s CNC machining shop, quality is paramount. We strive to deliver high-quality components while maintaining exceptional efficiency and precision. Our commitment to excellence means we not only meet but often surpass our clients’ expectations.

Comprehensive Outsourced Services

Our network includes a wide range of trusted and thoroughly vetted metal platers and finishers, both locally and nationwide. We recognize that the journey to perfection doesn’t end with metal CNC machining; a flawless finish is crucial to the final product.

SMF is equipped to handle custom CNC machining projects of all sizes, from small, low-volume orders to large-scale production runs. We possess the necessary resources and expertise to deliver your parts on schedule and within budget, ensuring your project’s success.

Lathe Parts

These lathe parts highlight the precision of our Y-Axis machining. The holes in the outer flange are cut by live tooling utilizing the Y-Axis, showing how we can machine complex custom CNC parts with high accuracy.

3-Axis Milling Expertise

This part shows our ability to tackle complex designs efficiently. Despite its complicated appearance, it’s a product of custom CNC machining with our 3-axis mill and simple second operation fixture. That’s all that was required to create it.

Low-Volume CNC Machining

Contact Us

Home » CNC Machining

How Can We Help You Today?

At Schantz Machine & Fabrication, we’re committed to supporting your projects from the initial design phase through to prototyping and full-scale production. Our team is dedicated to providing top-quality custom CNC parts crafted with precision and care to meet your specifications. With a track record of delivering on time and within budget, our CNC machining shop is here to ensure your project’s success.

Let us be your partner in turning your concepts into reality with our proven custom machining service. Our seamless custom CNC machining process guarantees satisfaction every step of the way. Talk to a CNC design consultant about your project.