Low-Volume CNC Machining

Benefits for Low-Volume Production

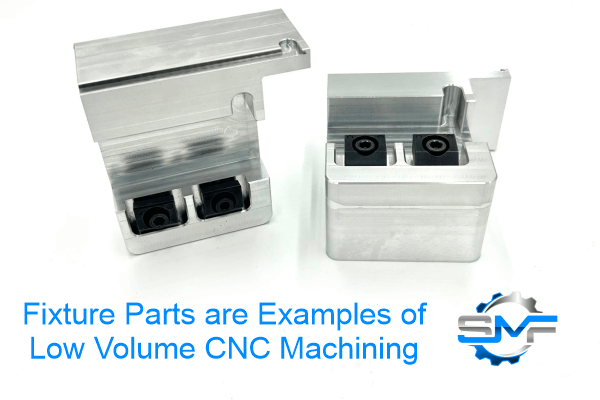

Low-volume CNC machining is the term often used for creating small batches of parts or prototypes. This technique enables manufacturers to produce high-quality parts in low quantities and at a reasonable price. Low-volume machining requires innovative work holding and streamlined production flows that minimize machine setup times. Schantz Machine & Fabrication excels at small batches and prototypes. Let us explain more about how we can keep your new product costs low.

What Is Low-Volume CNC Machining?

This type of machining, also known as computer numerical control machining, involves producing small quantities of metal parts using CNC machines. This method offers numerous advantages, such as cost-effectiveness, flexibility, and faster turnaround times. CNC machines can create complex designs with high precision, making them ideal for prototyping, small-scale production, and customized parts. Optimizing the design and choosing the right materials are critical factors that can enhance the benefits of low-volume CNC machining in complex industries.

What Capabilities Are Required for This Type of CNC Machining?

Certain capabilities are required to successfully achieve cost-effective, low-volume production. These include CNC milling, which allows for complex designs and tight tolerances, CNC turning for fast production speeds, subassembly for added value, and finishing processes that enhance product aesthetics.

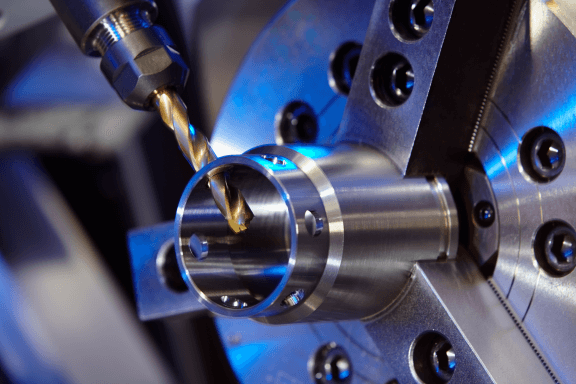

CNC Milling

CNC milling is a machining process that utilizes rotating multi-point cutting tools to remove material from a workpiece. It is perfect for manufacturing square or rectangular parts with pockets, holes, threads, and chamfered edges. The low-volume CNC machining method allows for high precision, tight tolerances, and repeatability, making it suitable for low-volume production runs. Industries such as automotive, aerospace, and electronics commonly use CNC milling due to its versatility in material options and applications.

CNC Turning

CNC turning is a low-volume machining process involving the rotation of a workpiece while a cutting tool removes material. It’s widely used in the automotive, aerospace, and medical industries. It offers tight tolerances, a variety of material choices, and the ability to machine complex parts with rotational symmetry. With low tooling costs and fast setups, CNC turning is suitable for high-mix requirements and high-quality production. It can produce cylindrical shapes and parts with off-center holes and pockets.

Finishing

Finishing is a critical process in low-volume CNC machining that improves product aesthetics, functionality, and corrosion resistance. It involves bead blasting, plating, laser marking, powder coating, and other surface treatment options. The automotive, aerospace, and consumer goods manufacturing industries commonly utilize finishing of some sort. Quality control, logistics, and packaging are crucial in dependable finishing processes.

Advantages of Low-Volume CNC Machining

This type of CNC machining offers flexibility for new product development, prototyping, and short production runs. It allows for high mix requirements, specific quality control, and material selection. Additionally, low-volume production runs minimize upfront costs, production process lead times, and material logistics. CNC machining provides high-quality, complex parts with tight tolerances, which is suitable for various industries. Additionally, it offers a wide range of machining capabilities, material options, and production process adjustments.

Lower Initial Costs

By avoiding high upfront costs associated with mass production, businesses can enjoy significant cost savings with low-volume machining. Furthermore, the ability to make adjustments during the prototyping phase further reduces overall production costs. With low-volume production, companies can minimize material usage and costs, all while maintaining high-quality standards. The numerical control technology employed in low-volume CNC machining ensures precision and accuracy without compromising on quality.

Quick Turnaround Time

This CNC machining method ensures fast lead time with short production runs. CNC machine tools enable efficient production, which reduces manufacturing process time. Small-scale production allows for necessary adjustments, which shortens production time. CNC machining offers quick production of complex parts, to meet tight deadlines.

Superior Precision and Accuracy

CNC milling and turning deliver high precision and tight tolerances, ensuring superior accuracy. Consistency and repeatability are guaranteed through CNC machining, which enhances product development. Additionally, a wide range of materials can be utilized to meet specific quality requirements in various industries.

Low-Cost or No-Cost Tooling

In low-volume production, the costs associated with injection molding or die-casting tooling are eliminated. Low-volume CNC machining offers the advantage of eliminating upfront tooling costs, making it efficient for low-volume production runs. With minimal machine setup required, initial production run costs are reduced. Furthermore, low-volume production with CNC machining eliminates the need for complex tooling and setup.

Fast and Easy Shipping

With small quantities and short runs, products can be quickly shipped to customers. The reduced time for quality control and fast production contribute to faster delivery. Low-volume production with CNC machining ensures efficient shipping, to meet tight deadlines.

Low-Volume Machining Tips to Save Time and Money

There are several things you can do to save time and money. First, it’s important to focus on simple and standard designs for your low-volume CNC machining needs, as this allows for easier and more efficient production. Secondly, using standard thread and hole sizes can help streamline the machining process. Lastly, considering the finishing process and its impact on cost and lead time is essential. By keeping these critical factors in mind, you can optimize your low-volume CNC machining projects.

Simple and Standard Designs

Simple and standard designs play a crucial role in low-volume CNC machining. They reduce the complexity of programming and setup, which saves both time and money. By using larger radii on inside pockets and corners, thickening thin walls, and using shorter wall features in general, you can cut machine costs considerably.

Use Standard Thread and Hole Sizes

Choosing standard sizes for threads and holes not only streamlines the design process but also simplifies communication with your machine shop. By using standard thread and hole sizes, your chances of the shop having this tooling in stock increase considerably. This can ultimately save time and money, making your low-volume CNC machining production more efficient. Incorporating standard drill sizes in your design can also positively impact the manufacturing process, ensuring accuracy and consistency across your product lines.

Considerations for Finishing

When it comes to finishing metal fabrication parts in low-volume machining, one popular option is anodizing. Anodizing not only provides corrosion resistance but also allows for the addition of color to the finished part. This critical factor is especially important in industries that require complex and intricate designs, as it helps enhance the overall aesthetics while ensuring durability.

Use Design for Manufacturing (DFM) in Part Designs

Proper design for manufacturing (DFM) is crucial for ensuring efficient production processes. When it comes to low-volume CNC machining, incorporating DFM principles can help optimize designs. This leads to reduced lead time and reduces the need for adjustments during production. Additionally, DFM ensures high-quality parts while minimizing waste.

Choosing the Right Partner for Your CNC Machining Needs

Assessing Expertise and Experience

To assess the expertise and experience of a machining partner, evaluate their track record in low-volume production runs. Consider their experience in complex industries and the manufacture of different types of parts. Look for their ability to meet specific quality requirements such as corrosion resistance, tight tolerances, and material specifications. Also, ensure they have the necessary quality control procedures and systems.

The Right Low-Volume CNC Machining Partner for Your Project Success

Look for a partner with a wide range of capabilities, from prototyping to mass production. Ensure they can handle various requirements such as small quantities, short production runs, and high mix needs. Additionally, seek a partner who offers value-added services like laser marking, assembly, material finishing, and sheet metal capabilities. Lastly, assess their ability to deliver high-quality, complex parts with tight tolerances.

Use Schantz Machine & Fabrication for Your Low-Volume CNC Machining Projects

Schantz Machine & Fabrication specializes in low-volume machining, handling complex designs with tight tolerances. Our state-of-the-art machine tools ensure high-quality parts production. By serving various industries, we excel at prototyping projects and offer efficient low-volume production capabilities for small quantities. Trust Schantz Machine & Fabrication for your low-volume CNC machining needs.

How Can We Help You Today?

From initial design to prototypes and full production, you can count on us to deliver quality parts on time and on budget!