Titanium vs Steel: Whats the Better Choice?

- Posted By: Zach Schantz

In the manufacturing world and the machining industry, titanium and steel are the top choices when it comes to using the strongest and most versatile materials to produce highly durable products. Although they have overlapping uses and applications, choosing one over the other is a challenging task because they bring different benefits to the table.

Both titanium and steel offer exceptional chemical and physical properties. Steel is primarily an iron-carbon alloy that is nearly always combined with other elements to form a wide range of steel types, each with distinctive characteristics. Similar to steel, titanium is also often alloyed with other metals (including steel) but can also be used in its pure elemental form. It is commonly used in high-performance applications and has a higher cost than steel.

This article will differentiate titanium and steel in terms of their characteristics, application, and machining capabilities.

Material Characteristics: Titanium vs. Steel

The question of which material is best for your project depends on your application and design constraints. It is best to understand first the material characteristics of titanium and steel to determine which one is more suitable to meet your requirements. Here are some significant differences between the two:

Composition

Titanium is a natural element found in pure and alloy forms. The most common titanium alloy is Ti 6-4, which is composed of aluminum and vanadium. On the other hand, steel is a byproduct of mostly iron and carbon, with varying quantities of other elements incorporated to refine its attributes. Steel alloys include stainless steel, high-carbon steel, and specific alloys such as 4130 and 4140.

Weight

Known for its low density and high strength-to-weight ratio titanium is relatively light in weight. Its densities usually vary a bit based on alloy, but it is fairly safe to say that titanium’s density (~4.5g/cm3) weighs less than 60% of steel (7.85 g/cm3 for carbon steel, and 8.03g/cm3 for stainless steel). This is why titanium is the preferred material for CNC machining in aerospace and other applications where weight must be minimized without compromising strength.

In contrast, steel alloys are heavier than titanium but are generally durable and suitable for applications where weight is not a design constraint. For instance, steel has 126 BHN (Brinell hardness number), which is almost double the hardness of titanium, which is only 70 BHN. Brinell hardness indicates the ability of a metal to resist permanent deformation.

Durability (Resistance to Corrosion & Extreme Temperature)

Many steel alloys outperform titanium in terms of strength and longevity. However, titanium stands out more when it comes to its exceptional corrosion resistance and capacity to withstand extreme temperatures.

The temperature has a significant effect on the ductility of metals. Titanium has a high melting point of 3,040°F (1,670°C). Steel’s melting point is up to 2,800°F (1.540°C) for carbon steel and 2,750°F (1.510°C) for stainless steel. Low temperature decreases ductility, while high temperature increases it.

In addition, steel alloys generally work well in various conditions, but the iron content makes them more prone to corrosion. Meanwhile, titanium works significantly better since it forms an oxide layer (layer of titanium dioxide) in the air that is not only very hard but also extremely resistant to corrosion and most chemicals that are not concentrated acids. Titanium is used in many harsh environments where constant exposure to chemicals, moisture, or other corrosive substances is anticipated.

Tensile Yield Strength

Titanium has greater strength per unit mass, but steel remains the superior choice for overall tensile yield strength.

Steel is an obvious choice if you consider material toughness as your primary requirement. But titanium is ideal for applications in which both strength and weight are essential to produce durable, lightweight parts.

Titanium vs Steel: Common Applications

Titanium is used in high-performance applications where superior heat properties, corrosion resistance, and a high strength-to-weight ratio are required. Titanium is commonly used in the following applications:

- Aircraft

- Armor plating

- Naval ships

- Motor parts

- Surgical tools

- Prosthetics

Steel and its alloys, on the other hand, are widely used in metal parts manufacturing, simple construction, and equipment development. You can also use them in the following applications:

- Electrical appliances

- Buildings and infrastructure

- Mechanical equipment

- Automotive

- Tools & Machinery

Machining Titanium vs Steel

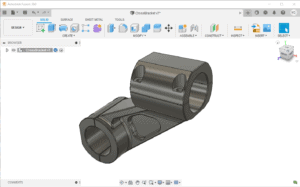

Titanium alloys are difficult to machine due to their high tensile strength, low ductile yield, 50% lower modulus of elasticity, and roughly 80% lower thermal conductivity than steel. These characteristics often cause the workpiece to spring back and/or overheat, leading to poor surface finish, accelerated tool wear, or worse.

You need to work with titanium machining experts to achieve high-quality titanium machined parts.

Unlike titanium, steel is generally easy to machine. One crucial consideration is that steel is much more brittle than titanium and more likely to shatter in cold temperatures (below roughly -20 to -40 degrees C, depending on the type of steel).

Titanium vs Steel: The Bottom Line

Choosing between titanium and steel is not a linear task. There are many factors to consider depending on your project’s unique requirements. It’s best to understand the fundamental properties of both materials before making your final choice. Better yet, we recommend consulting with machining experts to save time in determining the best material to use. This way, you will be provided with reasonable options suitable for your specific needs.

Work with Schantz Machine and Fabrication for High Quality Machining and Metalwork

Whether you choose titanium or steel for your custom parts, Schantz Machine & Fabrication is happy to assist you! We have in-house CNC machining and metal fabrication capabilities to produce custom parts per your prints. We also have decades of experience working with a huge variety of steel and titanium alloys.

We accept low-volume production machining and offer budget-friendly rates and the fastest turnaround time. Working with Schantz is working with hands-on, reliable machining experts who will deliver your design requirements and find the best possible solutions for your needs.

Other Articles of Interest

Titanium vs Steel Choice

Titanium vs Steel: Whats the Better Choice? In the manufacturing world and the machining industry, titanium and steel are the top choices when it comes

Top Challenges to Consider When Machining Titanium

Top Challenges to Consider when Machining Titanium Titanium’s high strength, high corrosion resistance, low weight, and other distinctive characteristics make it a material that is

What is Turning CNC Turning Milling for Custom Machining

What is Turning? CNC Turning & Milling for Custom Machining CNC machining encompasses several processes, the outcomes of which can include tools, parts, or components

What is a Custom Fabrication Shop a Review of Our Capabilities

What is a Custom Fabrication Shop? : A Review of Our Capibilities The Schantz family began building custom trailers and trucks for the food industry

How to Keep Costs Down with Low Volume Production Machining

How to Keep Costs Down with Low Volume Production Machining The biggest hurdle when it comes to low-volume production machining is the per-unit cost. This

Considering Tolerance: How to Save Money and Time on Custom Machined Parts

Customers sometimes ask how they can reduce the price of custom machined parts. Material is a factor, but on complex CNC parts, it’s often a small piece of the total cost…

How Can We Help You Today?

From initial design, to prototypes and full production,

you can count on us to deliver quality parts,

on time and on budget!