What is a Custom Fabrication Shop? : A Review of Our Capibilities

The Schantz family began building custom trailers and trucks for the food industry more than 60 years ago. Today, Schantz Machine & Fabrication is a full-service, family-owned-and-operated custom machine shop. Their metalworking expertise and reputation fueled growth in aftermarket racing products, dirt and pavement racing parts and accessories, suspension components, and various vehicle parts. Their goal is to provide economical, high-quality, customized, metal-fabricated parts with on time delivery.

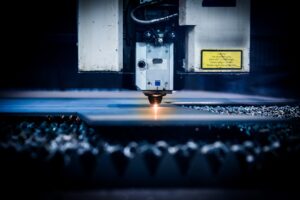

As a custom machine shop, Schantz strives to design and fabricate metal parts, including custom stainless-steel fabrication, to the tightest tolerances. Schantz Machine & Fabrication’s services include CNC machining, structural metal, welding, prototyping, fixturing, and low-volume production machining.

What it Means to be a Custom Fabrication Shop

The Fabricator describes custom fabrication shops as complex and difficult to define. Custom fabrication shops can fall anywhere in a broad manufacturing sphere: Precision sheet metal, precision tube, specialty fab, heavy plate, industrial, architectural, and structural. Where a fabrication shop finds itself within this sphere depends on its customer base and local market needs. Many shops are not easily pigeonholed within just one of these areas. A precision sheet metal fabricator might decide to invest in a plasma or waterjet and take on more heavy plate work. When looking for a fabrication shop, a customer should look for a mix of quality, equipment, and customer service. Some traits to expect from a custom fabrication shop include the ability to do precision work, high-end equipment and skilled machinists to run it, accurate cost estimates and delivery time, and customer service that reflects a commitment to meeting requirements and specifications.

Schantz Machine & Fabrication’s metal fabrication encapsulates a variety of processes, including structural fabrication; metal; tubing; and designing and building custom fixtures and functional prototypes. They combine traditional manufacturing methods with the latest technology and talent to fabricate all types of custom metal structures and assemblies to the exact requirements of their customers.

Custom metal parts fabrication at SMF includes the ability to work with a variety of raw materials, including aluminum, carbon steel, and custom stainless-steel fabrication. Schantz commonly uses titanium to machine suspension components, aftermarket parts, ATV parts, drag racing parts, and more. When necessary, Schantz Machine & Fabrication will source additional materials so that as much of the manufacturing process as possible is completed in-house.

CNC Machining, Low Volume Production Machining & Welding Services by Schantz Machine & Fabrication

Whether quoting an existing design or designing custom metal parts fabrications from scratch, Schantz Custom Fabrication is equipped with full-service machining centers, delivering high-speed machining that utilizes the latest technology. They also regularly employ 3D design and assembly processes to address the specific needs and requirements of each client.

As a custom fabrication shop, Schantz Custom Fabrication’s CNC machining services, welding, and fabrication services are rooted in their strong passion for racing and outdoor motorsports. They also count titanium welding among their strongest and most unique capabilities. As The Fabricator describes, while some fabricators and engineers shy away from welding titanium, experienced welders embrace it. Welding Headquarters calls titanium a highly reactive metal, which is why, in the past, people only welded it in tightly sealed chambers. However, with experienced welders, such as those at Schantz, and with proper gas shielding and preventative measures, titanium can be successfully and somewhat easily, welded.

Over the past 60 years, Schantz Custom Fabricators has established precise and efficient processes to design and build custom-fabricated parts that meet the strictest tolerances, including suspension components, dirt track racing parts, circle track racing parts, and accessories for ATVs, UTVs, and dirt bikes. Their expert staff frequently performs component modifications, custom metal parts fabrication, and crash recovery for midget cars, ATVs, UTVs, and other dirt track and pavement racing applications. From suspension systems and brakes to engine components and other modified racing gear, they have the in-house technology and engineering skills necessary to modify and straighten almost any kind of chassis, assembly, or component.

Larger Inside Radii Can Reduce

Machine Time, Cost & Improve Quality

Requiring 90-degree internal corners is an expensive ask. In most cases, it simply can’t be done; cutting tools are round, so sharp inside corners are more often than not impossible.

In many cases, the designer can allow for internal radiuses to cut down on manufacturing time and reduce the overall cost. Unless absolutely required, a part should always be engineered with rounded internal features and corners. The deeper the internal pocket, the larger the radius required. This allows the machinist to reach down to the bottom of your part with a larger diameter tool. Larger tools are more rigid and reduce the chances of chatter, which causes a poor surface finish.

There is a simpler way to think about this: if you are out driving in your car, you really must slow down and almost stop to make a sharp 90-degree turn. If the turn is much bigger or requires a bigger radius, you can keep your speed up. The same is true in machining.

Looser Part Tolerances Lead to Faster Machine Times

The more figures after a decimal point on a print, the higher the manufacturing cost. Many designers will default to tolerances that are tighter than required. The price difference between hitting +/- 10 thousand and +/- 2 can be dramatic. High precision parts require more final cutting passes to bring the part up to tolerance and extra quality assessment steps, ultimately slowing the entire process down.

Whenever possible, a part should be designed with the loosest tolerances possible. This allows for quicker manufacturing and a lower price tag. To help put things into perspective, the average human hair is about .003”, or three-thousandths of an inch. Rarely do parts really need to be that accurate, and if they do, it’s often certain features that need to be tighter as opposed to the full part.

About Schantz Machine and Fabrication

Schantz Machine & Fabrication is engineering and design-focused with the skills and experience to conduct a needs assessment with the customer and then design and fabricate custom metal parts using Autodesk Inventor and Fusion 360. While they are rooted in racing, Schantz is a proud U.S. source of custom metal parts fabrication for numerous industries.

A custom fabrication shop dedicated to working closely with customers, Schantz Custom Fabrication provides creative, precise, and efficient processes to design and build components to the strictest of tolerances. They ensure custom metal parts fabrication projects remain budget-friendly and are completed on time.

Other Articles of Interest

What Is CNC Laser Cutting?

What Is CNC Laser Cutting? Precision and efficiency are paramount when it comes to manufacturing and fabrication. It is for these reasons that the manufacturing

Titanium vs Steel Choice

Titanium vs Steel: Whats the Better Choice? In the manufacturing world and the machining industry, titanium and steel are the top choices when it comes

Top Challenges to Consider When Machining Titanium

Top Challenges to Consider when Machining Titanium Titanium’s high strength, high corrosion resistance, low weight, and other distinctive characteristics make it a material that is

How Can We Help You Today?

From initial design, to prototypes and full production,

you can count on us to deliver quality parts,

on time and on budget!