New CNC Machining Technology Trends for 2025

New CNC Machining Technology Trends for 2025 The CNC machining industry is on the cutting edge of technological advancement, often seeing early adoption of new

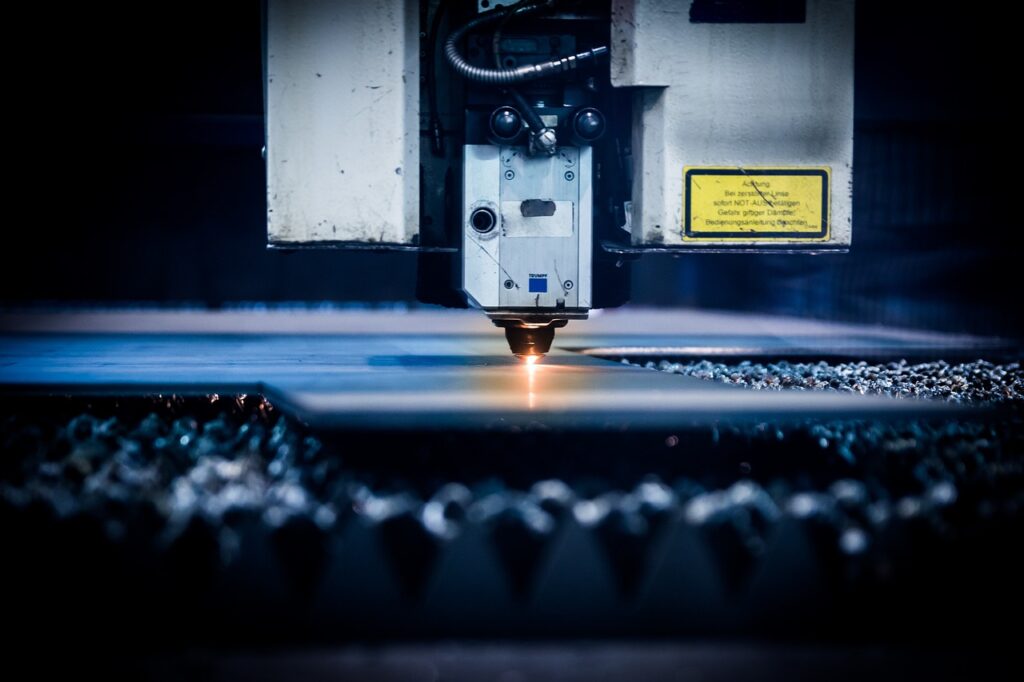

Precision and efficiency are paramount when it comes to manufacturing and fabrication. It is for these reasons that the manufacturing and fabrication industries are always looking for new and innovative ways to create precision products. CNC machining is at the forefront of this innovation, opening up near-limitless potential through computer-automated manufacturing methods. Among various CNC machining techniques, CNC laser cutting stands out for its ability to bring increased accuracy and precision to a wide range of manufacturing projects. In this article, we will delve into CNC laser cutting and how it fits into the world of CNC machining services.

CNC laser cutting is a CNC machining technique. To fully understand what it is and its potential, it is essential to first fully understand CNC machining.

CNC machining is an abbreviation for computer numerical controlled machining. In the CNC machining process, tool actions are automated based on each project’s unique G-code. This differs from traditional machining methods in which a human operator controls the movements and actions of tools. When comparing CNC machining to traditional machining, CNC machining can provide more efficiency, consistency, and allow for more complexity in product designs.

CNC laser machining is a specific type of CNC machining that employs a laser beam to cut through materials with extreme precision. The process utilizes a high-power laser to melt, burn, or vaporize material, leaving behind a clean and precise cut. Actions performed by the laser are controlled by the product’s unique G-code, created during the initial design process.

CNC laser cutting is an applicable technique for use across a variety of different CNC-machined materials, including both metals and plastics.

These are just a few examples of the materials that can be used in CNC laser machining. Choosing the right material is dependent on many factors, including intended use, budget, availability of materials, and more.

The ability to achieve complex and versatile designs makes CNC laser cutting a popular manufacturing technique for various types of industries. Here are a few examples:

CNC laser machining is one of many techniques used in CNC machining services. Here is how it compares to similar machining techniques:

CNC milling involves rotating cutting tools that remove material from a solid block. Like CNC laser cutting, CNC milling can create complex shapes and is useful for many different material types. But while they are both versatile techniques, CNC milling often requires more tool changes and setup time when compared to laser cutting.

CNC waterjet cutting is a process that involves a stream of high-powered water and abrasive material to cut through an object. The waterjet process is able to cut through thicker materials when compared to metals cut by CNC laser cutting. However, lasers provide a cleaner, more precise cut when working with thinner materials.

Plasma cutting uses a high-temperature plasma arc to cut through electrically conductive materials. When compared to CNC laser cutting, plasma cutting can often be completed with a lower budget but lacks the precision that laser techniques provide.

New CNC Machining Technology Trends for 2025 The CNC machining industry is on the cutting edge of technological advancement, often seeing early adoption of new

What Is a Custom Fabrication Shop?: A Review of Our Capabilities The Schantz family began building custom trailers and trucks for the food industry over

What Is CNC Laser Cutting? Precision and efficiency are paramount when it comes to manufacturing and fabrication. It is for these reasons that the manufacturing

Titanium vs Steel: Whats the Better Choice? In the manufacturing world and the machining industry, titanium and steel are the top choices when it comes

Top Challenges to Consider when Machining Titanium Titanium’s high strength, high corrosion resistance, low weight, and other distinctive characteristics make it a material that is

What is Turning? CNC Turning & Milling for Custom Machining CNC machining encompasses several processes, the outcomes of which can include tools, parts, or components

From initial design, to prototypes and full production,

you can count on us to deliver quality parts,

on time and on budget!

12344 IL-143

Highland, IL 62249

Quality Parts on Time and on Budget!