Home » Plastic CNC Machining

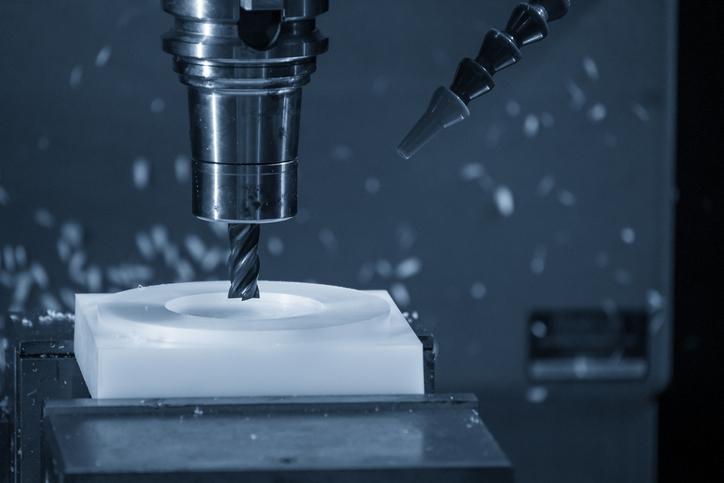

CNC machining is applicable to a number of different materials, including various types of plastics. By using automated computer technology, CNC machines, or Computer Numerical Controlled machines, have the ability to shape plastics into precision products. Plastic CNC machining is one of the most popular services we provide at Schantz Machine and Fabrication. Let’s discuss this method of production in more depth and discover how you can benefit from services such as plastic CNC milling.

CNC machines work by using a special computer code to direct the movement of tools. This code, known as “G-code,” is much like a road map for the manufacturing process. Special software integrates the G-code into the CNC machine to control drills, lathes, and other tools. Once the CNC machining process is complete, the final product is revealed after material has been shaved away to create a precision product.

Unlike 3D printing, which is an additive process, CNC machining plastic is a subtractive process. This means the initial material often comes in a block form and is bigger than the final product will be once completed.

Many different types of plastics can be used for CNC machining. Each plastic type has its own unique qualities and advantages. Here are a few of the most common plastic materials we work with:

When compared to traditional machining methods, plastic CNC machining holds many distinct benefits. Some of these benefits include:

CNC machining and plastic CNC milling open up near-endless possibilities for plastic products manufacturing. Whether you need just a single prototype or thousands of units, Schantz Machine and Fabrication has you covered. Talk to a CNC design consultant about your project and let’s get started!

From initial design, to prototypes and full production,

you can count on us to deliver quality parts,

on time and on budget!

12344 IL-143

Highland, IL 62249

Quality Parts on Time and on Budget!