Home » CNC Machining Materials

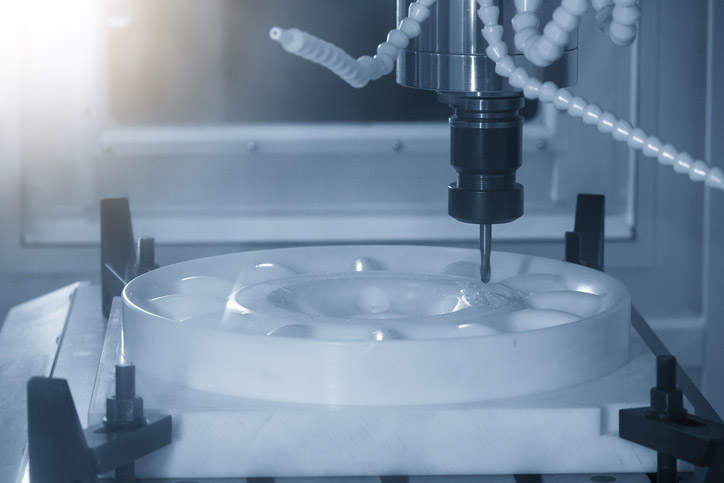

When it comes time to begin a CNC machining project, one of the first steps is determining the specific type of machining materials to use. At Schantz Machine & Fabrication, we specialize in CNC machining services for a wide range of applications, including automotive, aerospace, medical, and more. Here, we’ll share some insight into some of the most common CNC machining materials that we work with in our shop.

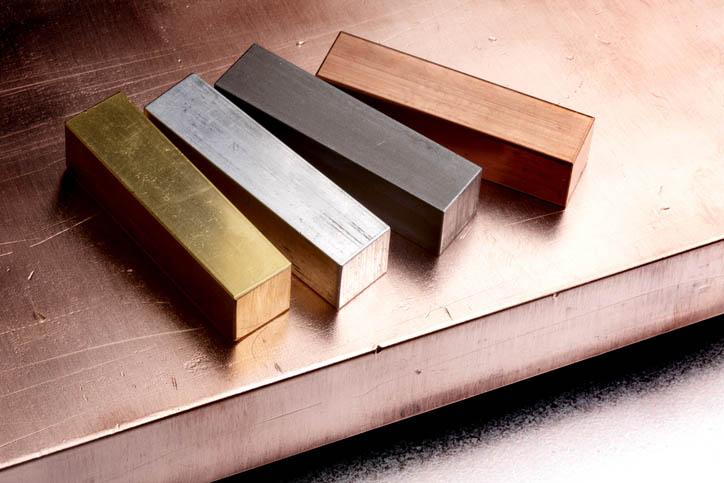

Metal is a very versatile material that can be applied to a wide range of CNC machining applications. Since different metals have different traits as CNC machining materials, it is vital to understand the unique qualities of various metals and how they differ from one another.

One of the most common metal CNC machining materials is aluminum alloy. It is a lightweight material that boasts an exceptional weight-to-strength ratio and can be very corrosion-resistant. Aluminum is available in various grades, including 2011, 6061, 6063, and 7075, each having its own distinct properties.

Made from copper and zinc, brass is a very soft metal that can be applied to many uses, including plumbing fixtures, furniture pieces, and firearms ammunition. Two common brass grades include brass 260 and brass 360.

Stainless steel is a popular material for many machining projects. Its strength makes it extremely resistant to wear and corrosion, making it a common choice for bolts, screws, and other construction materials. Available grades of stainless steel CNC machining materials include 303, 304, 316, 410, and 440c, among others.

Much like aluminum, titanium is very lightweight for the strength it provides. Titanium is resistant to corrosion, has strong heat conductivity, and is even biocompatible. This makes titanium a common CNC machining material for medical implants and other medical devices. Grade 5 (Ti 6Al-4v) is one of the most popular grades of titanium.

Bronze is another durable and corrosion-resistant CNC machining material. It is made from an alloy of tin, copper, and other elements. Bronze is a relatively easy material to machine and is commonly used for bearings, bushings, and wear strips. In fact, bronze 932 is known as bearing bronze as it is often an ideal material choice for various bearing applications.

Copper has excellent thermal and electrical conductivity, making it an ideal material for electrical components. It is also very common in jewelry production. Copper 110 and 145 are two common and versatile copper grades.

Depending on the nature of your project, plastics may be the ideal CNC machining material choice. While many types of plastic have low melting points that can make them challenging to machine, select plastic types can be an excellent choice for various CNC machining applications.

Nylon is one of the most widely used thermoplastics and is available in a variety of different variants. It is strong and durable; however, it can absorb moisture over time so it is not suitable for marine environments. Common applications include sprockets, gears, and sliding surfaces. Its lightweight structure makes Nylon an ideal CNC machining material for a wide range of applications.

ABS is another common plastic CNC machining material, renowned for its low cost and high machinability. It is resistant to impact, chemicals, and electrical current. ABS can also be colored very easily, and as such, is a common material choice for projects in which appearance is of critical importance.

Much like ABS, HDPE is impact-resistant and easy to machine. It is commonly used for shims, cams, and bushings. HDPE is also often used as a material for patio furniture and other outdoor applications.

PETG is a strong plastic material that is resistant to both chemicals and heat. Common applications include indoor signs and other commercial displays. It is comparable to polycarbonate but is often available at a lower price point.

UHMU has the highest impact strength of any plastic material currently available on the market. It is a low-friction material that also has self-lubricating properties. Examples of UHMU applications include mining chute liners, conveyor parts, body armor, and even golf ball cores.

Schantz Machine & Fabrication is here to help you every step of the way throughout your CNC machining project. Our CNC machining experts can answer your questions and provide valuable insight to help you choose the proper CNC machining material. Talk to a CNC design consultant about your project and let’s get started.

From initial design, to prototypes and full production,

you can count on us to deliver quality parts,

on time and on budget!

12344 IL-143

Highland, IL 62249

Quality Parts on Time and on Budget!