Top Challenges to Consider when Machining Titanium

- Posted By: Zach Schantz

Titanium’s high strength, high corrosion resistance, low weight, and other distinctive characteristics make it a material that is ideally suited for a wide range of medical, automotive, and aviation applications. Some of the top challenges to consider when machining titanium can challenge even the most experienced machinists.

The characteristics that make titanium desirable for many applications can also be the same reasons why it is difficult to machine. But with the right approach, it is possible to account for these issues and make the process of CNC machining titanium much less stressful and much more precise. It takes real machining expertise with solid experience using titanium to produce high-quality, high-precision titanium parts.

Schantz Machine and Fabrication specialize in titanium machining, welding, and assembly. We have over 6 decades of machining experience and are a reliable partner for machining and fabricating titanium, as well as most other metals.

What Makes Titanium Difficult to Machine?

There is a common misconception that Titanium is stronger than steel, when in fact, this is usually not the case. Steel is generally stronger than titanium (although this can vary widely depending on the alloys and heat treatments being compared), however, Titanium weighs only 40% of what steel does, making Titanium more suitable for applications where strength is important but weight must also be minimized. Below are some considerations when machining titanium:

Low Thermo Conductivity

Titanium is a thermal insulator. Compared to most other metals, the heat generated during the machining process is more difficult to conduct away, and this heat can accumulate around the work zone, which can eventually blunt the cutting tool or cause it to break completely. To manage this, there are several factors that machinists must adjust:

- Apply more coolant/cutting fluid to the work area. Additional coolant jets, higher flow rates, and tooling with through-tool coolant channels are some of the options that can be used.

- Minimize cutting speed. Tool speed plays a larger factor than feed rate when it comes to tool surface temperature. Therefore, it’s best to reduce the tool speed while maintaining the feed rate.

- Keep feeding. Do not allow the tool to dwell while in moving contact with the workpiece. Doing so can result in smearing, galling, work hardening, and tool breakage.

In addition to the above, it is important to replace the tooling if there is any sign of wear, because tool wear will quickly accelerate when machining titanium due to heat buildup.

Low Modules of Elasticity

Titanium has a lower modulus of elasticity than steel, meaning that it is more “springy” or “stretchy.” This characteristic implies that the workpiece will tend to move away from the machining tool unless heavy cuts and grips are maintained. Slender parts also tend to deflect under tool pressure, causing tool rubbing and friction, eventually leading to tolerance issues.

To address this problem, it is critical to understand the overall rigidity of the machining system and to use sharp, properly shaped cutting tools. The workholding solution is also critical when planning around Titanium’s lower rigidity to ensure clean-cutting performance. Custom workholding fixtures are frequently used, especially for parts that are thin in section and thus more affected by vibrations and tool pressure.

Variation of Chips Produced

In addition to a low modulus of elasticity, Titanium also has a relatively large elongation at break value; it will stretch to over 150% of its original length before breaking. This means that titanium tends to produce long chips that can easily damage the cutting tool and/or leave marks on the surface of the workpiece.

These long, thin chips do not aid heat transfer away from the work zone, so tooling that produces smaller and thicker chips is preferred wherever possible when machining titanium.

Built Up Edge (BUE)

Another major issue with titanium chips is the tendency for those chips to stick to the surface of the cutting tool, forming a “built-up edge”. This built-up titanium acts to dull the cutting edge of the tool, which can quickly lead to more heat buildup, tool wear, galling on the workpiece surface, and other disastrous effects.

Proper application of high-pressure cutting fluid directly to the cutting edge is key to clearing these chips before they can adhere to the tool, increasing the tool’s lifespan.

Precision Titanium Machining by

Schantz Machine & Fabrication

Schantz Machine and Fabrication offers CNC machining capabilities unparalleled to our competitors. We offer precision CNC milling and turning expertise, and we specialize in working with titanium. Our full-service CNC machining centers provide high-quality finished parts. We offer short turnaround time, reasonable rates, and we can assist you with designing for manufacturability.

Other Articles of Interest

New CNC Machining Technology Trends for 2025

New CNC Machining Technology Trends for 2025 The CNC machining industry is on the cutting edge of technological advancement, often seeing early adoption of new

What Is a Custom Fabrication Shop?: A Review of Our Capabilities

What Is a Custom Fabrication Shop?: A Review of Our Capabilities The Schantz family began building custom trailers and trucks for the food industry over

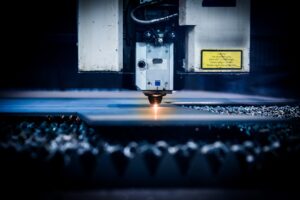

What Is CNC Laser Cutting?

What Is CNC Laser Cutting? Precision and efficiency are paramount when it comes to manufacturing and fabrication. It is for these reasons that the manufacturing

Titanium vs Steel Choice

Titanium vs Steel: Whats the Better Choice? In the manufacturing world and the machining industry, titanium and steel are the top choices when it comes

Top Challenges to Consider When Machining Titanium

Top Challenges to Consider when Machining Titanium Titanium’s high strength, high corrosion resistance, low weight, and other distinctive characteristics make it a material that is

What is Turning CNC Turning Milling for Custom Machining

What is Turning? CNC Turning & Milling for Custom Machining CNC machining encompasses several processes, the outcomes of which can include tools, parts, or components

How Can We Help You Today?

From initial design, to prototypes and full production,

you can count on us to deliver quality parts,

on time and on budget!