How to Find the Best Precision Machine Shop

8 Questions to Ask

- Posted By: Zach Schantz

CNC machine shops are like chefs in high-end restaurants; each has its own specialties, their preferred ways of working, and a hard-working team behind them. To ensure you get what you want, just as you would for a great meal, give some due diligence when looking for the precision machining parts shop for your project.

Search online for “precision machine shops near me” and you’re bound to get dozens of results. But the best way of finding what you need is by knowing exactly what you need. With that in mind, we’ve assembled a list of questions to help with your quest for top-notch machining services. You may be able to use some of these as filters to wittle down the list. For other questions, simply call or email the shop and ask what you want to know.

Distance: Which Machine Shops are Closest to Me?

Longer distance means slower delivery. If you’re expecting a quick turnaround, look for a machine shop that’s close to you. For rush jobs, they may be able to bring it to you when finished, or you may have the option to pick it up. That’s faster than FedEx or UPS, and it will give you the opportunity to pay the shop a visit and see what kind of operation they run.

CAD Packages: Can this Machine Shop Handle

my Models and Drawings?

With CATIA, Creo, AutoCAD, and SolidWorks among others, there are simply too many CAD products for a CNC machine shop to know and utilize them all. Be sure to tell a prospective shop what you use and have them confirm they’ll be able to handle your drawings. Alternatively, you can always ask what format they’d like to receive your models and drawings in.

What CNC Machining Capabilities does this Shop Have?

There’s no real definition of a “precision” machine shop, so it’s always best to ask about their machining capabilities. CNC equipment provides accuracy and repeatability, but it’s important to ask if they turn, mill, grind, and cut, not to mention the machines they do it on. Newer equipment will probably be more accurate, although some of the older cast iron base machines are hard to beat. If they offer an equipment list, check it for maximum weights and sizes, especially if your parts are larger.

Experience: Has this Shop Worked with this

Type of Material?

If you only design in 6xxx series aluminum and low carbon steel, skip this question. But if you’re using stainless, brass, magnesium, or more exotic materials such as Inconel or titanium, ask what experience they have. There are some tricks to machining these and getting accuracy and a good finish; the same applies to welding them. You don’t want your job to be their learning experience!

Accuracy: Can this Machine Shop Meet the Precision I Require?

A clean, well-organized CNC machine shop should be able to meet general tolerances, follow GDT, and minimize part-to-part variability. If you need especially tight tolerances, talk to the shop in advance. They may be able to offer an alternative approach, suggest a particular machining process, or they may even decline to quote.

Does this Shop have a Minimum Order Quantity?

CNC machining is perfect for small batches, but some shops like to minimize setup time with substantial minimum order quantities. If you only need a few parts, it’s always best to ask ahead of time.

Does this Shop Specialize in Machining Parts for Special Industries

A precision machining parts shop owner may focus on a particular niche. For example, some stick to medical device work, some are into aerospace, and others specialize in motorsports. A shop that knows your industry will likely deliver the best results because they’ll understand the expectations that aren’t spelled out in print.

What Inspection Equipment does this Machine Shop have?

Some shops use a granite table and a height gauge, while others have a high-end CMM in a temperature-controlled room. Think about what needs checking on your parts, and whether you need an inspection report or even NIST traceability before spending on extra services.

Welding is a special case because visual inspection may not be enough to assure quality. If you’re having parts welded, consider asking if the shop can organize or perform weld inspection.

Schantz Machine and Fabrication Offers

Precision Machining for Your Project

While all machine shops have the ability to cut metal, you should really aim to work with a shop that understands your requirements and expectations. Rather than picking a shop simply based on price or convenience, it is important to ask the questions that will result in the best possible product. Schantz Machine & Fabircation is where machining experience and efficiency meet; we encourage you to explore our website and contact us to find out if we’re the best shop to meet your needs.

Other Articles of Interest

New CNC Machining Technology Trends for 2025

New CNC Machining Technology Trends for 2025 The CNC machining industry is on the cutting edge of technological advancement, often seeing early adoption of new

What Is a Custom Fabrication Shop?: A Review of Our Capabilities

What Is a Custom Fabrication Shop?: A Review of Our Capabilities The Schantz family began building custom trailers and trucks for the food industry over

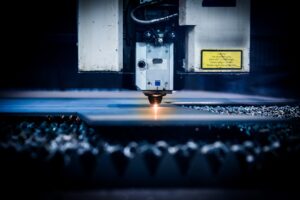

What Is CNC Laser Cutting?

What Is CNC Laser Cutting? Precision and efficiency are paramount when it comes to manufacturing and fabrication. It is for these reasons that the manufacturing

How Can We Help You Today?

From initial design, to prototypes and full production,

you can count on us to deliver quality parts,

on time and on budget!