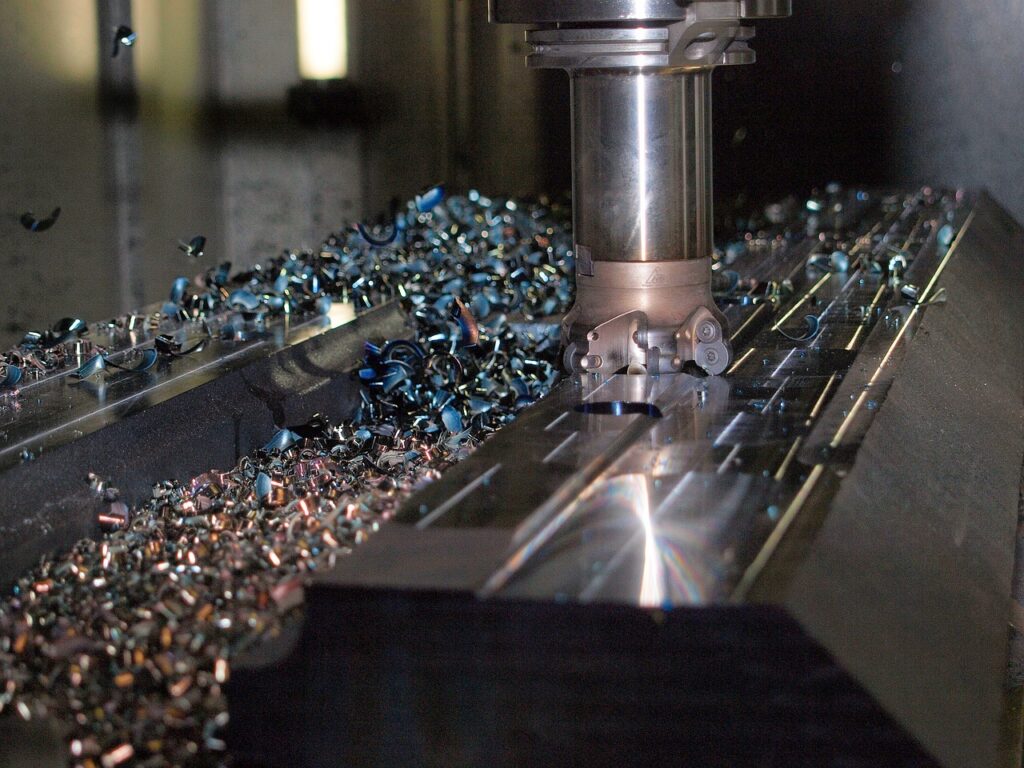

3D CNC machining is an advanced manufacturing process that utilizes computer-controlled tools to create three-dimensional products with extraordinary precision. While traditional machining methods require manual adjustments and offer limited versatility, 3D CNC machining, also known as 3D computer numerical-controlled machining, employs the use of automated technology. Special coding is made through CAD software to create the blueprint for the final product.

Our 3D CNC machining services allow us at Schantz Machine & Fabrication to produce a wide range of complex product shapes with high consistency and minimal waste. From prototypes to small batches to large-scale production runs, this technique can be an excellent choice for your next product.

There are many reasons to consider 3D CNC machining services. Here is what you can expect from our services at Schantz Machine & Fabrication:

Look no further than Schantz Machine & Fabrication for your next machining project. Our process looks a bit like this:

3D CNC machining is a versatile process for creating a wide range of precision products across industries such as aerospace, automotive, medical supplies, and more. Contact our team to learn more about our machining services and how Schantz Machine & Fabrication can help you bring your product to life.

Home » 3D CNC Machining

From initial design, to prototypes and full production,

you can count on us to deliver quality parts,

on time and on budget!

Quality Parts on Time and on Budget!