Home » Acrylic CNC Machining

Acrylic is a versatile thermoplastic known for both its durability and transparent appearance. Through CNC machining of this material, acrylic can be shaped into many different products for a wide range of uses. Find out more about the acrylic CNC machining and acrylic CNC milling processes below. When you’re getting quotes or need to quote you next CNC machining project, we invite you to reach out to our expert team at Schantz Machine and Fabrication.

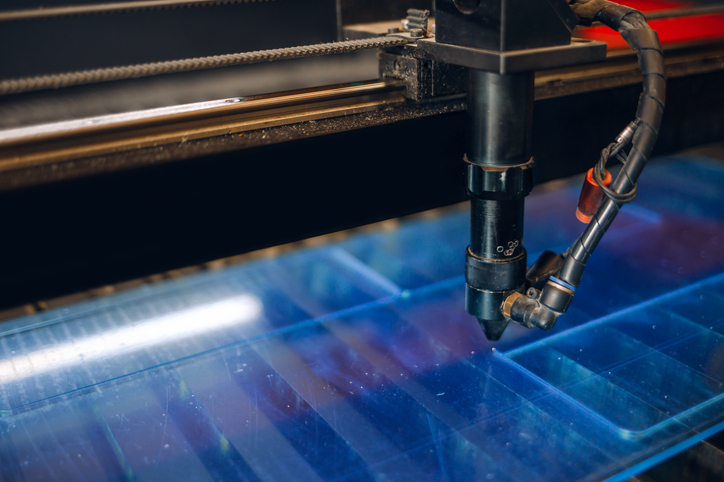

CNC machining is simply the abbreviated term for Computer Numerical Controlled machining, a process by which tools are moved by computer automation to create an acrylic product. The process begins with an idea for a product that is then designed using computer-aided design (CAD) software. Once designed, the product’s unique G-code is integrated into the CNC machine to act as a road map for the movement of tools. This process differs from traditional acrylic machining in which the machine is controlled by a human operator.

Acrylic is another name for polymethyl methacrylate, or PMMA. There are numerous qualities of acrylic that make it an ideal choice for many different CNC-machined products, including:

You likely come across acrylic CNC-machined products every day without even realizing it. Its versatility means it can be applied to retail settings, the medical industry, home products, and more. Here are just a few examples of products created by acrylic CNC machining:

Acrylic is a very versatile material that can be used for a number of different product applications. If you are looking to manufacture an acrylic CNC-machined product, look no further than Schantz Machine and Fabrication. We are a family-owned shop with extensive acrylic CNC machining experience, including acrylic CNC milling. Our experts are here to help you through every step of the process to ensure the success of your product. Upload your design file for a free quote on production costs within 24 hours.

From initial design, to prototypes and full production,

you can count on us to deliver quality parts,

on time and on budget!

12344 IL-143

Highland, IL 62249

Quality Parts on Time and on Budget!