Home » CNC Machining » CNC Turning

CNC Turning Services

Multi-Axis Turning

Schantz Machine & Fabrication offers the latest in CNC turning services technology. Our Y-axis and live tooling-equipped lathes allow for additional features like milling, drilling, and tapping off the centerline of the part. This typically leads to a done-in-one part that saves time and increases accuracy. Turn to SMF for all your CNC turning needs.

CNC Turning Centers with Y-Axis and Live Tooling

Best for High Accuracy, Complicated Parts Such As:

Parts with features off-center like grooves, flats, and holes.

Features at a 90-degree angle to the center of rotation.

Parts with large pocketed areas for weight reduction.

Our CNC turning services combine advanced Y-axis and live tooling capabilities to produce highly accurate and complex parts efficiently. Our technology allows us to create innovative designs and achieve significant weight reductions in parts, providing you with faster turnaround times and superior-quality products.

What is a Y-axis and What Does it Do?

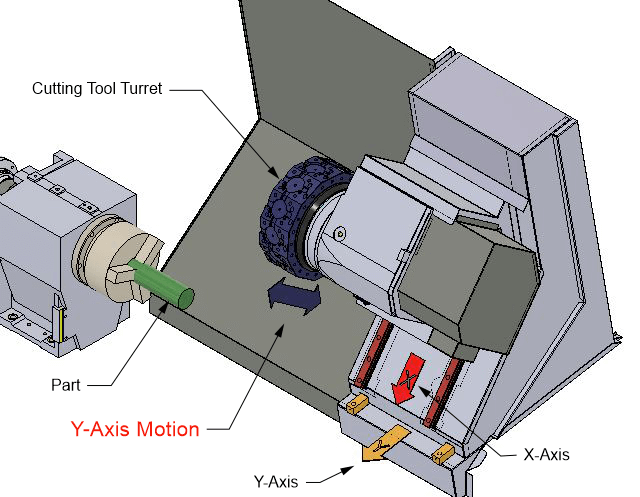

A CNC metal turning center with a Y-axis is a type of CNC lathe service with additional reach to create features on a part off the centerline. The Y-axis is typically perpendicular to the X-axis, which is the main axis that moves both in and out of the part. On most CNC metal turning machines of this type, the combination of the X- and Y-axis movement allows for its extended range outside the centerline of the part.

Y-Axis Motion

Shown here as part of our CNC turning service, you can see the X-axis in red and the Y-axis in yellow which both move together to create the Y-axis motion (dark blue). This additional motion allows for tool movement off the centerline of the part.

This movement combined with live tooling allows for a more complex part without multiple setups, and with the added benefit of increased accuracy.

Live tooling is especially useful for things like drilled holes or pockets both radially and axially to the center line or “Z-” axis of the part.

CNC Turning with Live Tooling

Live tooling is a term used to describe the ability of a CNC turning machine to perform certain machining operations, such as drilling, milling, and tapping, while the workpiece is still clamped in the main work holding chuck. The live tooling is a core part of our CNC turning service and is driven by a dedicated motor separate from the main spindle. An easy way to think of this is it’s like having a whole separate mill attached to the end of a traditional lathe.

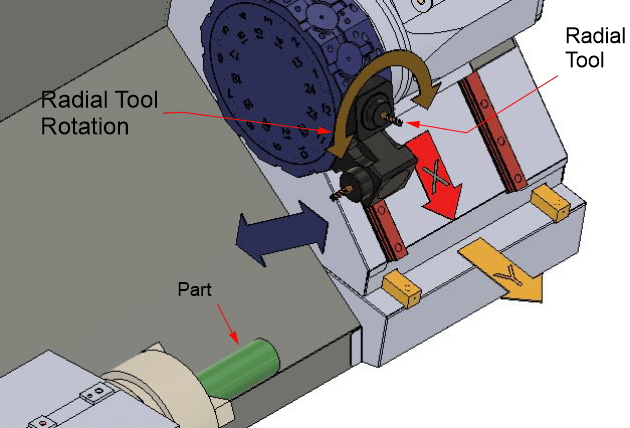

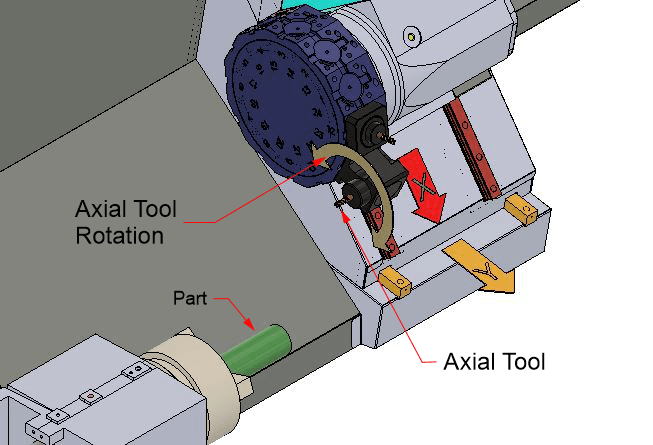

Live tooling is available in many different configurations, but two of the most common are radial and axial orientations. Essential to our CNC lathe service, axial tools are good for part features that are in line with the part, and radial tools can add features that are at 90 degrees to the part.

Radial Tool Orientation

A Radial tool orientation is a live tool that is mounted at 90 degree’s to the center line of the part.

Axial Tool Orientation

An Axial tool is orientated to run with the length of the part or along with the “Z” Axis of the part.

What are the Benefits of Live Tooling?

Every machinist knows that the more you can do in one CNC turning service setup, the better your parts will be. Moving parts to and from additional setups is both time-consuming and can cause a loss of accuracy each time you move.

In many cases, having live tooling allows a machine shop to produce the part right off the main chuck, effectively reducing the setups to zero.

Y-axis & Live Tooling Combined can Machine Parts Such As:

Motor Shafts

Slotted Bushings

Threaded Shafts with Keyways

Sprayer Nozzles

Custom Bolts & Pins

Custom Nuts

Couplings

Materials for Our CNC Turning Services

We carry a wide selection of metals that can be used with our CNC turning and lathe services, including aluminum, brass, low-carbon steel, stainless steel, steel alloy, and titanium. Whatever your specific needs or industries served may be, we have the right material for the job.

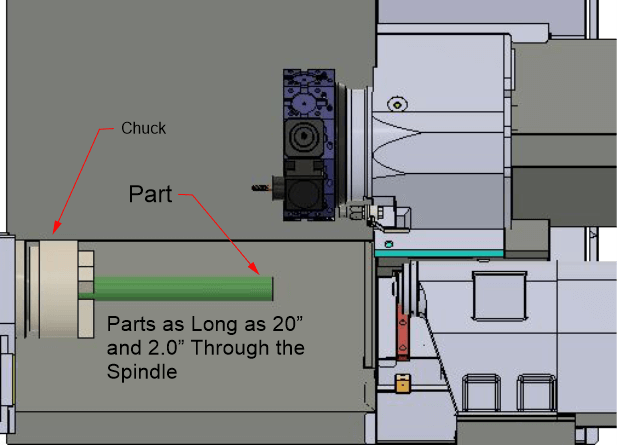

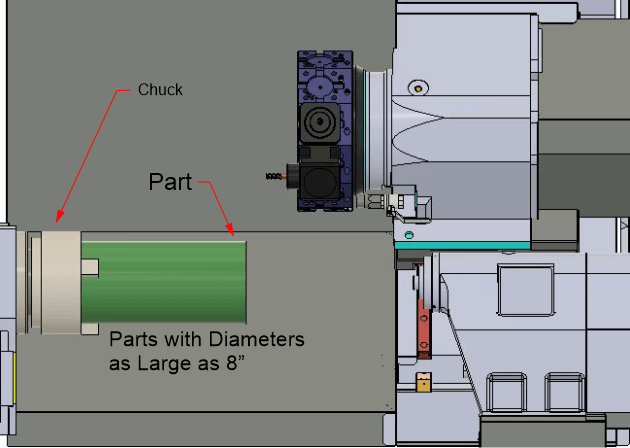

General Part Sizes for CNC Turning

Our CNC turning centers can process diameters up to 2.0” through the spindle, with chucking capacities up to 8” and a work-length piece capacity of 20”. Our state-of-the-art equipment and experienced team allow us to offer a vast range of solutions, whether you need benefits such as increased length, internal machining, or budget-friendly pricing for small production runs.

Through Spindle Size

SMF can process through spindle parts up to 2.0″ in diameter and 20″ long.

Chucked Part Size

Chucking capacities as large as 8″ in diameter

CNC Turning and Milling Services: Give SMF a Try!

Getting a quote for any of our CNC turning and milling services means clear and timely communication to keep your projects moving along.

At SMF, Your Success is Our Success!

Contact Us

How Can We Help You Today?

From initial design, to prototypes and full production,

you can count on us to deliver quality parts,

on time and on budget!