Schantz Machine and Fabrication Blog

Titanium vs Steel Choice

Titanium vs Steel: Whats the Better Choice? In the manufacturing world and the machining industry, titanium and steel are the top choices when it comes

Top Challenges to Consider When Machining Titanium

Top Challenges to Consider when Machining Titanium Titanium’s high strength, high corrosion resistance, low weight, and other distinctive characteristics make it a material that is

What is Turning CNC Turning Milling for Custom Machining

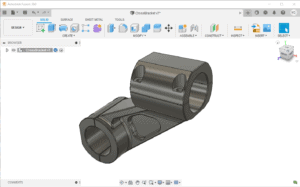

What is Turning? CNC Turning & Milling for Custom Machining CNC machining encompasses several processes, the outcomes of which can include tools, parts, or components

What is a Custom Fabrication Shop a Review of Our Capabilities

What is a Custom Fabrication Shop? : A Review of Our Capibilities The Schantz family began building custom trailers and trucks for the food industry

How to Keep Costs Down with Low Volume Production Machining

How to Keep Costs Down with Low Volume Production Machining The biggest hurdle when it comes to low-volume production machining is the per-unit cost. This

Considering Tolerance: How to Save Money and Time on Custom Machined Parts

Customers sometimes ask how they can reduce the price of custom machined parts. Material is a factor, but on complex CNC parts, it’s often a small piece of the total cost…

How to Find the Best Precision Machine Shop for Your Project: 8 Questions to Ask

CNC machine shops are like chefs in high-end restaurants; each has its own specialties, their preferred ways of working, and a hard-working team behind them. To ensure you get what you want, just as you would for a great meal, give some due diligence when looking for the precision machining parts shop for your project.

How to Avoid Defects When Welding Titanium | Custom Welding Services

Titanium has characteristics that make it unique. When you need strength, low weight, and corrosion-resistance, you ask for titanium.

Custom Machined Parts: How to Keep Your CNC Machining Costs Down

Custom Machined Parts: How to Keep Your CNC Machining Costs Down When it comes to CNC machined parts, finding the right manufacturing company to work

Home » Schantz Machine and Fabrication Blog

How Can We Help You Today?

From initial design, to prototypes and full production,

you can count on us to deliver quality parts,

on time and on budget!